Food Core Chilling

Pilot Unit Determines Design Parameters of Steam-Jet Vacuum Equipment for Production Plants

Designing Parameters for the Efficient Recovery of Fatty Acids & Oils Entrained in Steam Pilot Unit Determines Design Parameters of Steam-Jet Vacuum Equipment for Production Plants: The efficient recovery of fatty acids and oils entrained in the deodorizing steam has the economic advantages of minimizing product loss and pollution in condenser water. To determine design and operating parameters for a fullscale production unit, a pilot unit was set up as a means of establishing flow rates, pressure, vacuum, temperature, load, type of mist eliminator and other factors that would operate most efficiently on a plant production scale.

The equipment in the pilot plant includes a 24 in. diameter Scrub-Vactor; a 12 sq ft, type 22-A ARM plate type heat exchanger; a 112 sq ft vapor-in-tube surface condenser with condensate tank; a 11,4 in. gear pump with steam turbine drive; a two-stage, noncondensing Evactor.

The equipment was assembled as shown in the accompanying diagrams. The Scrub-Vactor is a combination of a jet-venturi fume scrubber and parallel flow condenser, which uses the product itself as the scrubbing medium.

Measured amounts of air, dry superheated steam and fatty acids are admitted to the Scrub-Vactor at a temperature of approximately 300 F, and a pressure of approximately 2 in. of Hg absolute. The inlet material is joined by a stream of distillate released at about 135 F and a pressure of 100 psig. The distillate is sprayed into the receiving area at just under atomization conditions. The inlet material and the distillate mixture is drawn into the venturi where they are thoroughly mixed and it is cooled to approximately 150 F. The distillate and the heavy oils which are condensed from the inlet mixture are returned to the charge at the bottom of the vessel. The charge is kept at a constant level by bleeding off the excess. The temperature is kept constant by circulation through the plate heat exchanger and returned to the high press spray nozzle.

The high temperature, high pressure distillate motivates the flow and scrubs and condenses the vapor mixture being fed in. The purified water vapor remains in the vapor state because of the relatively high temperature, and passes upward through a mist eliminator and then into the surface condenser from which it is discharged. An extremely small amount of oil-laden vapor will pass through the scrubber in accordance with Dalton’s Law of Additive Pressures.

Most runs of the pilot plant operation showed the efficiency resulted in a better than 95% recovery of the fatty acid oils. Samplings of the oils in the condensate showed a negligible contamination.

Weighted condensate samples were taken by inserting a tube into the condenser and drawing off a suitable amount of the fluid. Xylene was added to the sample to absorb 11ny fatty oils that may have been present. The xylene and its absorbed oil (if any) floated to the surface and the sample was decanted leaving only the xylene mixture. Heat was then applied to drive off the xylene mixture. The amount of residual fatty oil remaining was formulated with the amount present in the inlet mixture and equated to a figure representing an efficiency percentage: Efficiency= 1-(% oil residue/% oil inlet) = 95%

The residue figure was also checked by measuring the increase in distillate over a period of time and subtracting it from the amount of inlet oil.

During the test runs the heat transfer ratios for the plate cooler were worked out empirically for the various oils tested. These figures have proved valid when extrapolated for process equipment.

From the test logs and observations, it is apparent that production plant design and operating parameters were established and that the efficiency of the pilot tests could be simulated in full scale plant production.

Results also show that a Scrub-Vactor recovery unit can be placed in line in a continuous process equipment scheme without interrupting the functioning of the other chemical processing equipment as there is a minimal loss of pressure in this set-up.

Analysis and calculation of the test data results prove that the test data are practical as criteria for full scale equipment selection and operation. Also, use of the pilot unit assures an exceptionally high percentage of waterfree product recovery and low contaminant condenser water.

Thermal Recompression Saves Steam and Water in Evaporators

Recompression of spent process steam in evaporators is one of the measures being used by the Food Processing Industry in its growing effort to conserve energy, according to Croll Reynolds Company of New Jersey, designers and manufacturers of thermocompressors and high-vacuum systems for the process industries.

Thermal Recompression: Thermocompression, as applied to evaporators, particularly in the Food Industry, is a process by which a portion of the steam discharged from an evaporator effect is captured and compressed to a higher pressure and temperature for re-use. This is accomplished by a thermocompressor which entrains and compresses low-pressure spent steam for reuse at a higher pressure in the initial effect of a multiple-effect evaporator. A thermocompressor is similar to, and operates on, the same principle as a steam jet ejector used for producing a vacuum.

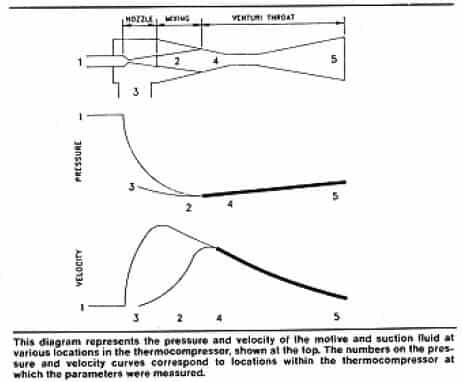

Croll Reynolds thermocompressors consist of three basic parts: nozzle, mixing chamber, and diffuser. These sections function passively to entrain and compress a low-pressure fluid, such as spent steam, to some higher pressure. The recompressed fluid can then be used elsewhere, and its heat reclaimed.

In operation, high-pressure steam, as a motivating fluid, enters and expands through the converging-diverging nozzle to the mixing chamber. Pressure drops sharply and the velocity increases rapidly as the steam leaves the nozzle. The suction fluid, low-pressure steam enters and mixes with the motivating steam in the mixing chamber. The mixture is then recompressed to an intermediate pressure as it passes through the diffuser.

The overall efficiency of the steam thermocompressor can be expressed as a function of the entrainment efficiency. Because of impact and turbulence, there is an unavoidable loss of kinetic energy when the high-velocity motive fluid entrains the slower suction fluid. The kinetic energy of the mixture that results is only a fraction of that originally possessed by the motive fluid. The fraction that is successfully transferred to the mixture through the exchange of momentum is referred to as the “entrainment efficiency.” A portion of the motive energy is absorbed by the mixture as heat and therefore produces an increase in enthalpy.

Thermal Recompression: Thermocompression, as applied to evaporators, particularly in the Food Industry, is a process by which a portion of the steam discharged from an evaporator effect is captured and compressed to a higher pressure and temperature for re-use. This is accomplished by a thermocompressor which entrains and compresses low-pressure spent steam for reuse at a higher pressure in the initial effect of a multiple-effect evaporator. A thermocompressor is similar to, and operates on, the same principle as a steam jet ejector used for producing a vacuum.

Croll Reynolds thermocompressors consist of three basic parts: nozzle, mixing chamber, and diffuser. These sections function passively to entrain and compress a low-pressure fluid, such as spent steam, to some higher pressure. The recompressed fluid can then be used elsewhere, and its heat reclaimed.

In operation, high-pressure steam, as a motivating fluid, enters and expands through the converging-diverging nozzle to the mixing chamber. Pressure drops sharply and the velocity increases rapidly as the steam leaves the nozzle. The suction fluid, low-pressure steam enters and mixes with the motivating steam in the mixing chamber. The mixture is then recompressed to an intermediate pressure as it passes through the diffuser.

The overall efficiency of the steam thermocompressor can be expressed as a function of the entrainment efficiency. Because of impact and turbulence, there is an unavoidable loss of kinetic energy when the high-velocity motive fluid entrains the slower suction fluid. The kinetic energy of the mixture that results is only a fraction of that originally possessed by the motive fluid. The fraction that is successfully transferred to the mixture through the exchange of momentum is referred to as the “entrainment efficiency.” A portion of the motive energy is absorbed by the mixture as heat and therefore produces an increase in enthalpy.

Two Systems Compared: The value of thermal decompression can be seen with a comparison of multiple-effect evaporation by itself to multiple-effect evaporation with thermal decompression. A straight, steam-heated, triple-effect falling film evaporator processing whey would require at 270 lb/hr, 90 degrees F water at 31,5 gal/min, and 163 ft squared of heat transfer surface to produce120 lb/hr of product at 50% solids from 1,000 lb/hr of feed at 6% solids. Thus, water is evaporated at 880 lb/hr, 3.25 pounds for each pound of input steam. If thermocompression is used, steam and water requirements for the same service are reduced to 172 lb/hr and 20.3 gal/min, respectively, although the steam pressure is required to be 110 psig. The needed heat transfer surface is reduced to 154 ft squared and 5,12 pounds of water are evaporated for each pound of input steam.

The evaporator equipped with a thermocompressor uses 36% less steam and 36% less water than the straight steam evaporator when both are operating at at rate of 800 lb/hr. In addition, the evaporator equipped with a thermocompressor actually uses less heating surface than the straight steam system. This is because more evaporation is done in the first effect at low concentration, and less evaporation in the subsequent effects at higher concentration where the heat transfer coefficient is lower.

In the Food Processing Industry, product sensitivity dictates low evaporating temperatures; hence, the entire system operates under vacuum. In such plants, the boiler room usually produces steam at greater than 100 psig. Boiler room steam, therefore, must be reduced to sub-atmospheric pressure and must be desuperheated before it can be used in the evaporator, causing a substantial loss of available energy. Using thermal decompression on evaporators, high-pressure steam passes into a thermocompressor through nozzles, transforming the pressure energy that would be otherwise lost into kinetic energy of such magnitude that substantial quantitates of used low-pressure steam can be withdrawn from the evaporator and compressed for re-use. It has been found that 172 lb/hr of high-pressure steam is capable of compressing 306 lb/hr of spent steam from the first effect, resulting in a total steam feed to the evaporator of 478 lb/hr. The remainder of the falling-film triple-effect evaporator is similar to the straight steam system, except the second and third effects are smaller as a result of reduced duty.

As the Food Processing Industry continues its drive to reduce fuel costs and improve product quality, more plants will switch to multiple-effect evaporation systems. For these new systems, as well as for existing multiple-effect evaporators that can be retrofitted with thermocompressors, thermal recompression is a practical method for reducing over-all production costs.

Two Systems Compared: The value of thermal decompression can be seen with a comparison of multiple-effect evaporation by itself to multiple-effect evaporation with thermal decompression. A straight, steam-heated, triple-effect falling film evaporator processing whey would require at 270 lb/hr, 90 degrees F water at 31,5 gal/min, and 163 ft squared of heat transfer surface to produce120 lb/hr of product at 50% solids from 1,000 lb/hr of feed at 6% solids. Thus, water is evaporated at 880 lb/hr, 3.25 pounds for each pound of input steam. If thermocompression is used, steam and water requirements for the same service are reduced to 172 lb/hr and 20.3 gal/min, respectively, although the steam pressure is required to be 110 psig. The needed heat transfer surface is reduced to 154 ft squared and 5,12 pounds of water are evaporated for each pound of input steam.

The evaporator equipped with a thermocompressor uses 36% less steam and 36% less water than the straight steam evaporator when both are operating at at rate of 800 lb/hr. In addition, the evaporator equipped with a thermocompressor actually uses less heating surface than the straight steam system. This is because more evaporation is done in the first effect at low concentration, and less evaporation in the subsequent effects at higher concentration where the heat transfer coefficient is lower.

In the Food Processing Industry, product sensitivity dictates low evaporating temperatures; hence, the entire system operates under vacuum. In such plants, the boiler room usually produces steam at greater than 100 psig. Boiler room steam, therefore, must be reduced to sub-atmospheric pressure and must be desuperheated before it can be used in the evaporator, causing a substantial loss of available energy. Using thermal decompression on evaporators, high-pressure steam passes into a thermocompressor through nozzles, transforming the pressure energy that would be otherwise lost into kinetic energy of such magnitude that substantial quantitates of used low-pressure steam can be withdrawn from the evaporator and compressed for re-use. It has been found that 172 lb/hr of high-pressure steam is capable of compressing 306 lb/hr of spent steam from the first effect, resulting in a total steam feed to the evaporator of 478 lb/hr. The remainder of the falling-film triple-effect evaporator is similar to the straight steam system, except the second and third effects are smaller as a result of reduced duty.

As the Food Processing Industry continues its drive to reduce fuel costs and improve product quality, more plants will switch to multiple-effect evaporation systems. For these new systems, as well as for existing multiple-effect evaporators that can be retrofitted with thermocompressors, thermal recompression is a practical method for reducing over-all production costs. Thermocompressor Reduces Distiller’s Steam Use

A Thermocompressor installed at McGuinness Distillers’ Toronto facility has resulted in a 25% reduction in live steam demand and provided the company with a maintenance-free system. Payback time was less than two years.

The thermocompressor steam conservation system was made operational after the 1981 summer shutdown. A flash tank, Croll Reynolds ejector, two pumps, some piping changes and instrumentation were all that was required. The components were all started on the first day of operation and the operators adapted quickly to the new system which does not increase the complexity of starting up the column.

The ejector consists of five basic parts: a variable spindle-operated nozzle, mixing chamber, diffuser, steam chest and spindle actuator. The 6′ x 6′ x 2 1/2′ spindle nozzle is a special feature which allows for variable operation without any instability or loss of efficiency.

Instead of a standard fixed orifice, which can also be adapted to this operation, the nozzle and spindle assembly combines a rounded entrance orifice with a straight section into which a tapered spindle is guided. Its operation is very much like that of a needle valve.

Spindle-operated units are used where suction and discharge pressure vary greatly, requiring large compensating changes in motive fluid flow. Such is the case at McGuinness where the motive steam is at a pressure of 100 psi and the user steam is at a pressure of 8 psi. In this way higher efficiencies are obtained by maintaining high motive pressures rather than by wasteful throttling.

Summary & Results: The McGuinness distillation system is a practical demonstration of the principle of thermal recompression. The high pressure steam passing through the thermocompressor captures the heat (in the form of steam vapor) that would otherwise be lost. This becomes Kinetic energy of such magnitude that a substantial quantity of low pressure steam is recovered and compressed for reuse in the beer column.

Our Croll Reynolds system resulted in a 25% reduction in live steam demand and provided us with a maintenance free system with a less than two year payback. It has been our most practical system for reducing overall production and energy costs.

The thermocompressor steam conservation system was made operational after the 1981 summer shutdown. A flash tank, Croll Reynolds ejector, two pumps, some piping changes and instrumentation were all that was required. The components were all started on the first day of operation and the operators adapted quickly to the new system which does not increase the complexity of starting up the column.

The ejector consists of five basic parts: a variable spindle-operated nozzle, mixing chamber, diffuser, steam chest and spindle actuator. The 6′ x 6′ x 2 1/2′ spindle nozzle is a special feature which allows for variable operation without any instability or loss of efficiency.

Instead of a standard fixed orifice, which can also be adapted to this operation, the nozzle and spindle assembly combines a rounded entrance orifice with a straight section into which a tapered spindle is guided. Its operation is very much like that of a needle valve.

Spindle-operated units are used where suction and discharge pressure vary greatly, requiring large compensating changes in motive fluid flow. Such is the case at McGuinness where the motive steam is at a pressure of 100 psi and the user steam is at a pressure of 8 psi. In this way higher efficiencies are obtained by maintaining high motive pressures rather than by wasteful throttling.

Summary & Results: The McGuinness distillation system is a practical demonstration of the principle of thermal recompression. The high pressure steam passing through the thermocompressor captures the heat (in the form of steam vapor) that would otherwise be lost. This becomes Kinetic energy of such magnitude that a substantial quantity of low pressure steam is recovered and compressed for reuse in the beer column.

Our Croll Reynolds system resulted in a 25% reduction in live steam demand and provided us with a maintenance free system with a less than two year payback. It has been our most practical system for reducing overall production and energy costs. For your vacuum system requirements, contact our US headquarters in Parsippany or our representative offices in your area.