Combination of ejectors and vacuum pump improves efficiency.

Problem: In choosing a new high-vacuum system for fractional distillation, Polarome Manufacturing Company, New York, NY and Newark, NJ, a producer of high-quality flavor and fragrance chemicals, considered reliability and performance the most important factors. Rising utility costs made steam consumption of the system another prime consideration.

Flavor and fragrance chemicals are heat sensitive at the moderately high temperatures of their atmospheric boiling points. Distillation is carried out under vacuum to minimize thermal degradation. For stable operation, the vacuum system for the distillation column has to be ultra-reliable, and has to be able to go on-line quickly. Fluctuations in vacuum affect operating temperature and fractionation and cause deterioration of the product quality.

Solution: Polarome’s process requires a gas removal rate from the distillation column of 7.5 lb/hr of air plus 7.5 lb/hr of condensable vapors at 0.5 mm Hg absolute pressure at 105° F. After evaluating various types of vacuum systems, mechanical systems were ruled out because the necessary volume of flow would require a more complex system, elevating cost and horsepower requirements. An all steam-jet ejector system would require too much steam.

Consequently, Polarome chose a combination ejector/liquid ring pump system that combines the two distinctly different types of equipment to improve high-vacuum efficiency. The unit requires only 400 lb/hr of motive steam at 125 psig, and the liquid ring pump only draws 5.7 brake hp.

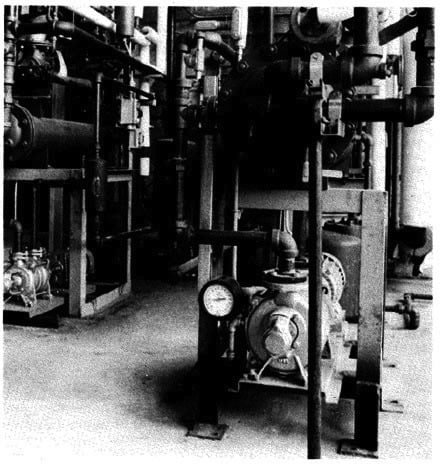

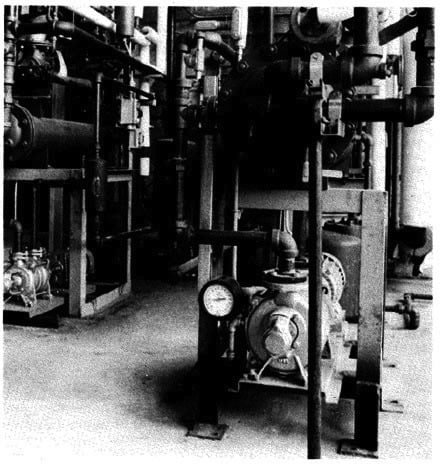

Polarome purchased two virtually identical four-stage systems, each composed of two ejector stages, a shell-and-tube condenser, and a two-stage liquid ring vacuum pump. The fully packaged systems were delivered skid-mounted, ready to pipe and operate.

In operation; the process gases and vapors to be handled by the system are drawn through the suction inlet of the first stage ejector and compressed by the two ejector stages to a shell-and-tube condenser. This interstage condenser cools and partially condenses the gas/vapor stream, reducing the volume of the load to be handled by the liquid ring vacuum pump. The pump serves as a final compression stage and also handles the condensate from the condenser as it drains directly into the pump’s suction port.

For installations where water supply may be a problem, partial and full sealant recovery systems are available for the liquid-ring pump. The hybrid system can also be designed to operate using low motive steam pressures in the 5-10 psig range.

By: CP Staff

Flavor and fragrance chemicals are heat sensitive at the moderately high temperatures of their atmospheric boiling points. Distillation is carried out under vacuum to minimize thermal degradation. For stable operation, the vacuum system for the distillation column has to be ultra-reliable, and has to be able to go on-line quickly. Fluctuations in vacuum affect operating temperature and fractionation and cause deterioration of the product quality.

Solution: Polarome’s process requires a gas removal rate from the distillation column of 7.5 lb/hr of air plus 7.5 lb/hr of condensable vapors at 0.5 mm Hg absolute pressure at 105° F. After evaluating various types of vacuum systems, mechanical systems were ruled out because the necessary volume of flow would require a more complex system, elevating cost and horsepower requirements. An all steam-jet ejector system would require too much steam.

Consequently, Polarome chose a combination ejector/liquid ring pump system that combines the two distinctly different types of equipment to improve high-vacuum efficiency. The unit requires only 400 lb/hr of motive steam at 125 psig, and the liquid ring pump only draws 5.7 brake hp.

Polarome purchased two virtually identical four-stage systems, each composed of two ejector stages, a shell-and-tube condenser, and a two-stage liquid ring vacuum pump. The fully packaged systems were delivered skid-mounted, ready to pipe and operate.

In operation; the process gases and vapors to be handled by the system are drawn through the suction inlet of the first stage ejector and compressed by the two ejector stages to a shell-and-tube condenser. This interstage condenser cools and partially condenses the gas/vapor stream, reducing the volume of the load to be handled by the liquid ring vacuum pump. The pump serves as a final compression stage and also handles the condensate from the condenser as it drains directly into the pump’s suction port.

For installations where water supply may be a problem, partial and full sealant recovery systems are available for the liquid-ring pump. The hybrid system can also be designed to operate using low motive steam pressures in the 5-10 psig range.

By: CP Staff

Flavor and fragrance chemicals are heat sensitive at the moderately high temperatures of their atmospheric boiling points. Distillation is carried out under vacuum to minimize thermal degradation. For stable operation, the vacuum system for the distillation column has to be ultra-reliable, and has to be able to go on-line quickly. Fluctuations in vacuum affect operating temperature and fractionation and cause deterioration of the product quality.

Solution: Polarome’s process requires a gas removal rate from the distillation column of 7.5 lb/hr of air plus 7.5 lb/hr of condensable vapors at 0.5 mm Hg absolute pressure at 105° F. After evaluating various types of vacuum systems, mechanical systems were ruled out because the necessary volume of flow would require a more complex system, elevating cost and horsepower requirements. An all steam-jet ejector system would require too much steam.

Consequently, Polarome chose a combination ejector/liquid ring pump system that combines the two distinctly different types of equipment to improve high-vacuum efficiency. The unit requires only 400 lb/hr of motive steam at 125 psig, and the liquid ring pump only draws 5.7 brake hp.

Polarome purchased two virtually identical four-stage systems, each composed of two ejector stages, a shell-and-tube condenser, and a two-stage liquid ring vacuum pump. The fully packaged systems were delivered skid-mounted, ready to pipe and operate.

In operation; the process gases and vapors to be handled by the system are drawn through the suction inlet of the first stage ejector and compressed by the two ejector stages to a shell-and-tube condenser. This interstage condenser cools and partially condenses the gas/vapor stream, reducing the volume of the load to be handled by the liquid ring vacuum pump. The pump serves as a final compression stage and also handles the condensate from the condenser as it drains directly into the pump’s suction port.

For installations where water supply may be a problem, partial and full sealant recovery systems are available for the liquid-ring pump. The hybrid system can also be designed to operate using low motive steam pressures in the 5-10 psig range.

By: CP Staff

Flavor and fragrance chemicals are heat sensitive at the moderately high temperatures of their atmospheric boiling points. Distillation is carried out under vacuum to minimize thermal degradation. For stable operation, the vacuum system for the distillation column has to be ultra-reliable, and has to be able to go on-line quickly. Fluctuations in vacuum affect operating temperature and fractionation and cause deterioration of the product quality.

Solution: Polarome’s process requires a gas removal rate from the distillation column of 7.5 lb/hr of air plus 7.5 lb/hr of condensable vapors at 0.5 mm Hg absolute pressure at 105° F. After evaluating various types of vacuum systems, mechanical systems were ruled out because the necessary volume of flow would require a more complex system, elevating cost and horsepower requirements. An all steam-jet ejector system would require too much steam.

Consequently, Polarome chose a combination ejector/liquid ring pump system that combines the two distinctly different types of equipment to improve high-vacuum efficiency. The unit requires only 400 lb/hr of motive steam at 125 psig, and the liquid ring pump only draws 5.7 brake hp.

Polarome purchased two virtually identical four-stage systems, each composed of two ejector stages, a shell-and-tube condenser, and a two-stage liquid ring vacuum pump. The fully packaged systems were delivered skid-mounted, ready to pipe and operate.

In operation; the process gases and vapors to be handled by the system are drawn through the suction inlet of the first stage ejector and compressed by the two ejector stages to a shell-and-tube condenser. This interstage condenser cools and partially condenses the gas/vapor stream, reducing the volume of the load to be handled by the liquid ring vacuum pump. The pump serves as a final compression stage and also handles the condensate from the condenser as it drains directly into the pump’s suction port.

For installations where water supply may be a problem, partial and full sealant recovery systems are available for the liquid-ring pump. The hybrid system can also be designed to operate using low motive steam pressures in the 5-10 psig range.

By: CP Staff