About Us

About

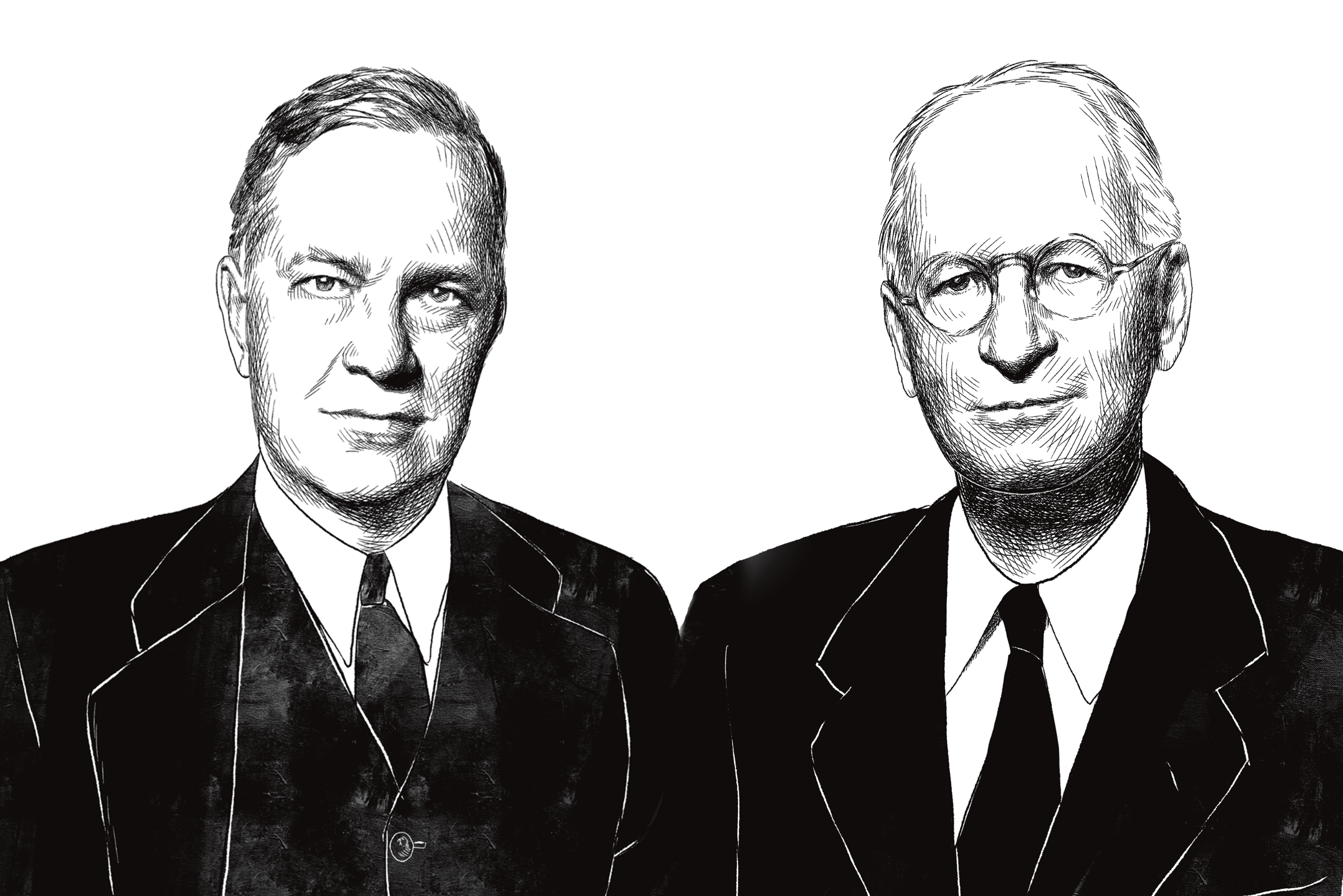

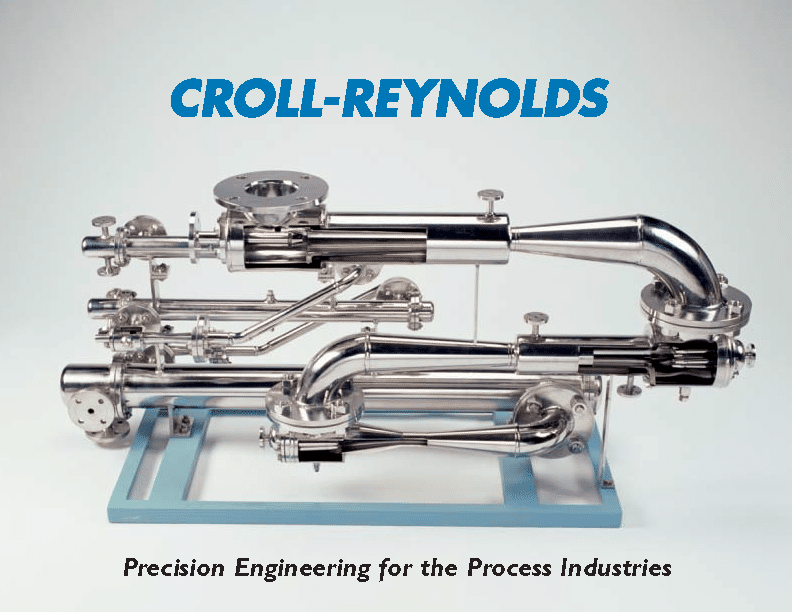

Croll Reynolds was founded in 1917 by two engineering colleagues with a vision for how steam jet ejectors would advance industrial science and transform modern life. We continue to build on this mission by meeting the technological needs of today’s leading innovators.

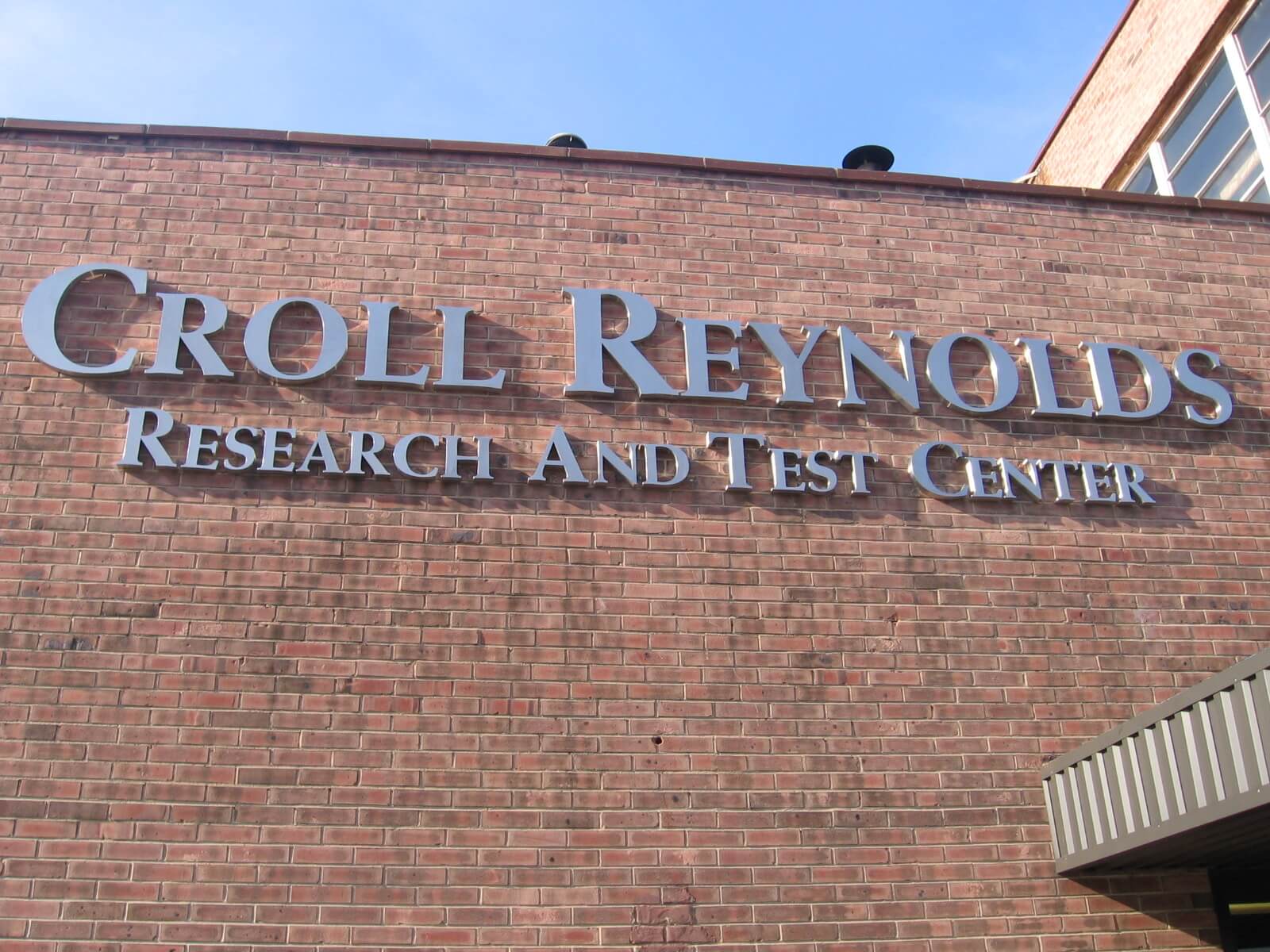

Our Research and Test facility

Croll Reynolds products undergo extensive quality inspection and testing at our facility in Teterboro, NJ. Product testing and analysis is conducted by our on-site engineers to ensure that every commission meets quality criteria and functions according to exact project specifications prior to release.

The Croll-Reynolds nameplate represents our guarantee that your critical process components have been optimized for real-time conditions and scenarios. Our engineering team utilizes simulation programs including ANSYS Fluent, VMG, and ASPEN to validate our theoretical designs; diligently reviewing all calculations and verifying drafting according proprietary sizing and design tools. This along with our testing controls, support our final product evaluation.

Our Mission

Croll-Reynolds’ strength lies in its ability to solve complex vacuum processing challenges.

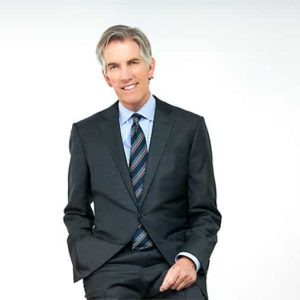

From the Desk of Samuel W. Croll, III

In a connected world, countries, governments and companies also have character, and their character-how they do what they do, how they keep their promises, how they make their decisions, how things really happen inside, how they connect and collaborate, how they engender trust, how they relate to their customers, to the environment and to the communities in which they operate-is now their fate – Dov Seidman, author of “How: Why How We Do Anything Means Everything in Business (and in Life).”

For many firms, “how they do what they do, how they keep their promises, how they make their decisions, how things really happen inside” are the new metrics. At Croll Reynolds, these questions have always served as a basis from which we operate. They will continue to guide us regardless of the shifting economic landscape.

We operate in an environment where intricate processes, complex supply chains and distant markets present daily challenges. If we are to keep our promises, connect and collaborate with our colleagues in the Process Industries, and make informed decisions that inure not only to our benefit but to the benefit of our customers, our focus must remain on our character and integrity as an organization.

At heart, Croll Reynolds is an engineering firm. The key to our success lies in the intrinsic value that we add to our customers’ processes. Everything we do centers on that value proposition. To that end, our response to a request for quote is a thorough analysis rather than a boiler-plate reply. As a matter of course, our engineers collaborate with our customers rather than present one-size-fits-all solutions. Our support staff understands the imperative of timely delivery and is prepared with real time information rather than best-guess assumptions. And when problems arise, as they inevitably do, we spare no effort or expense in their resolution.

These are the promises that we have kept for over 90 years…through two World Wars and the Great Depression. They are a reflection of our character and integrity as an organization. We hope that you share our vision and invite you to work with us to address your process needs.

Samuel W. Croll III

100 years of Engineering Excellence

November 15, 1917

The Liberty Equipment Corporation with offices at 95 Liberty Street in New York City was formed. Two weeks later, Philip E. Reynolds, as Secretary of the Corporation, enters into an agreement with Samuel W. Croll, who is elected President and General Manager.

April 2, 1918

At the third meeting of the Board of Directors, the name of the Corporation was changed to Croll Reynolds Company Inc. and the Firm moved its offices to 17 John Street.

1920s-1930s

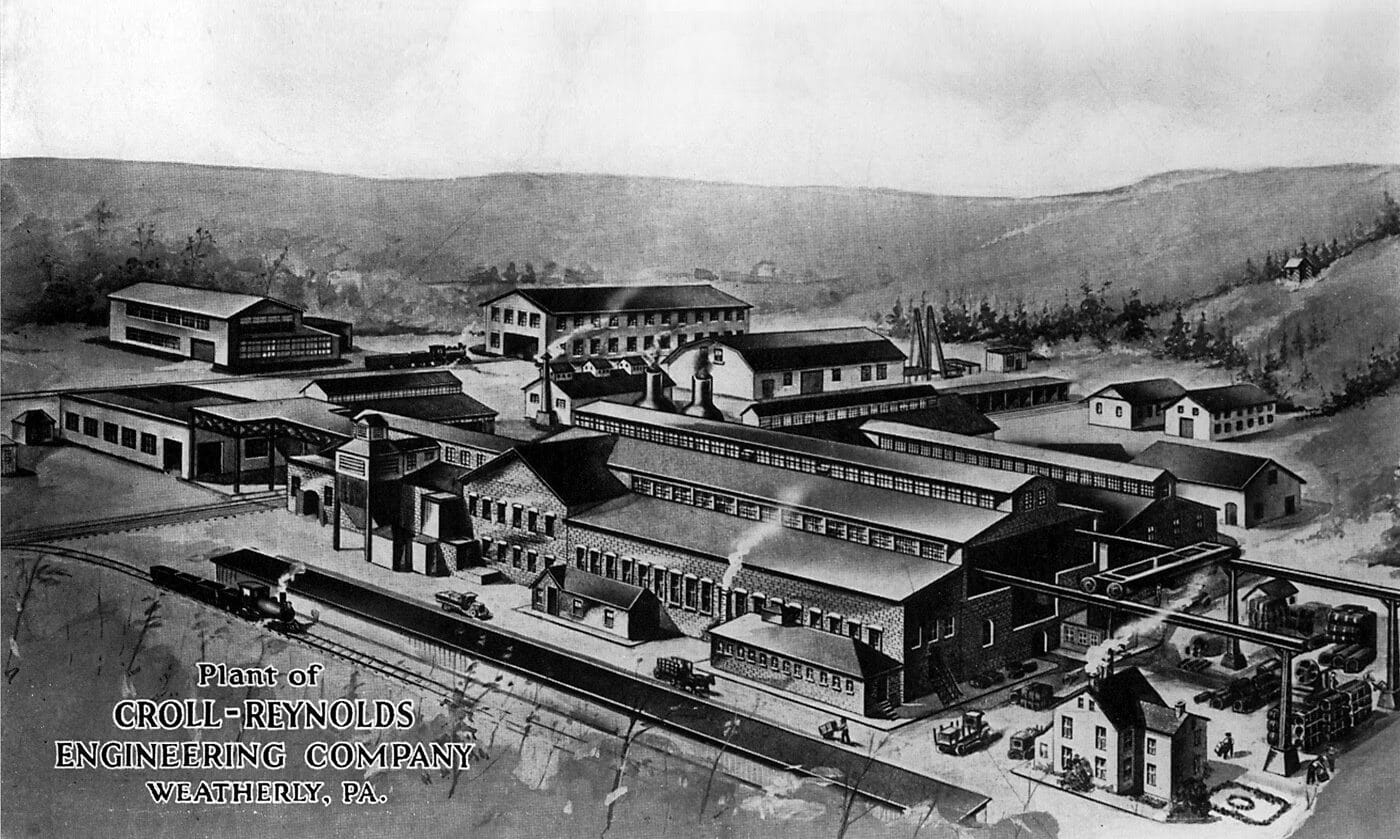

As demand for process vacuum equipment grew in the 1920s, the company turned to the Weatherly Foundry for the manufacture of its equipment. In the late 1930s, Croll Reynolds formed a relationship with the E. Wortmann Machine Works that endures today under its own third generation of leadership.

1940s-1950s

Upon graduating from LeHigh University, after his service as an officer in the Army-Air Force, Samuel W. Croll Jr. joins Croll Reynolds. Shortly thereafter, James T. Reynolds, a recent graduate from Duke University also joins the company. In 1951, the Firm relocated to New Jersey, and opened its Research and Test Facility in Teterboro. Under the helm of this second generation, Croll Reynolds solidifies its position as the preeminent domestic supplier of ejector-based vacuum technology.

1960s-1970s

Croll Reynolds has focused on applications engineering as a growth vehicle for much of its history; seeking out applications where jet ejector technology is the best technical solution to generating a process vacuum. As a result, the company has developed a broad customer base in a variety of industries from chemical processing, pharmaceutical, fibers, and beyond. Its designs became a critical component of the United States’ Lunar Landing Mission in the late sixties.

1980s-1990s

Croll Reynolds designs take part in the space race and development of the Strategic Defense Initiative. This era ushered in the third generation to the firm. Philip E. Reynolds, an Engineering graduate of Notre Dame, and Samuel W. Croll III, a graduate of Yale and New York Law School, join the firm and follow in the footsteps of their forefathers. In 1989, Henry Hage joined the company, his understanding of customer needs and value-added sales, positions the firm to begin capturing more of the international market.

2000s-2010s

Croll Reynolds moved its offices to Parsippany, New Jersey, in April of 2005. With its Process Vacuum Division on a sound footing under the leadership of Henry Hage, the Company turned its attention to the growing demand for Air Pollution Control equipment. However controversial, the issues of global warming and the sustainability of our environment have been pushed to the forefront of the national dialogue. With the formation of The Clean Air Group and Cross Rip Ocean Engineering, Croll Reynolds engineering brings over forty years of design experience to the task at hand.

2020s

Under the mentorship of the current management team, Philip E. Reynolds III and Daniel Hage, begin their careers at Croll Reynolds. In working together with an experienced team of engineering professionals, they bring the same sense of personal pride to their work in service our century-long commitment to quality, dependability, innovative research, and above all, customer service.