A Thermocompressor installed at McGuinness Distillers’ Toronto facility has resulted in a 25% reduction in live steam demand and provided the company with a maintenance-free system. Payback time was less than two years.

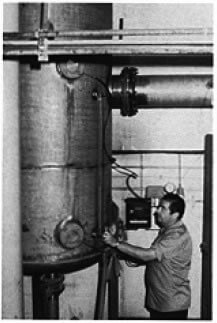

Installation of a thermocompressor at McGuiness Distillers’ Toronto plant has provided the distiller with a method of capturing and recompressing steam for reuse while simultaneously reducing energy costs in the still operation. The four columns that produce spirit use about 14,000 lbs. of steam/hour. The largest user of steam is the beer column which strips the alcohol, produced during fermentation, from the mash. The stillage leaves the base of the column at about 220 degrees F and is then passed through a centrifuge to remove corn fines which are sold as cattle feed. The need to reduce steam consumption and the high temperature of this effluent led to the idea of recovering this heat by the principle of a jet ejector system. An ejector is a simplified type of vacuum pump or compressor which has few moving parts. It consists essentially of a steam nozzle that discharges a high velocity jet across a suction chamber that is connected to the equipment to be evacuated. The gas, in this case steam vapor, is entrained by the steam and carried into a ventri-shaped diffuser which converts the velocity energy of the steam into pressure energy. The idea of a thermocompressor system for application at McGuinness was the responsibility of Mike Delevante (technical services manager). He was assisted by Gord Dine (plant manager) and Charlie Hayler who was in charge of the project. Consultation with Stone & Webster led to the installation of the system which utilizes a Croll Reynolds Jet Ejector, for evacuating vapor from the hot stillage that passes through a large vacuum tank at the base of the column. The Croll Reynolds ejector is mounted atop of a 500-gallon tank and high pressure steam (100 psi) is passed through the ejector. Liquid at a temperature of 220 degrees F passes from the base of the still through the tank at a constant rate. The vacuum created by the ejector lowers the temperature in the vacuum tank thus releasing low pressure steam vapor which is entrained by the high pressure steam. The motive steam plus entrained vapor is then used to heat the still and the net result is that less motive steam is used for the still operation. It has been found that, properly designed, an ejector can “pick up” about 25% of the steam required from the effluent, and in the case cited, a steam saving of 1500 lb/hr has been realized on the beer column. The other advantage is that there is a resulting temperature drop in the effluent and the stillage no longer has to be cooled prior to going to the centrifuges.

The thermocompressor steam conservation system was made operational after the 1981 summer shutdown. A flash tank, Croll Reynolds ejector, two pumps, some piping changes and instrumentation were all that was required. The components were all started on the first day of operation and the operators adapted quickly to the new system which does not increase the complexity of starting up the column. The ejector consists of five basic parts: a variable spindle-operated nozzle, mixing chamber, diffuser, steam chest and spindle actuator. The 6′ x 6′ x 2 1/2′ spindle nozzle is a special feature which allows for variable operation without any instability or loss of efficiency. Instead of a standard fixed orifice, which can also be adapted to this operation, the nozzle and spindle assembly combines a rounded entrance orifice with a straight section into which a tapered spindle is guided. Its operation is very much like that of a needle valve. Spindle-operated units are used where suction and discharge pressure vary greatly, requiring large compensating changes in motive fluid flow. Such is the case at McGuinness where the motive steam is at a pressure of 100 psi and the user steam is at a pressure of 8 psi. In this way higher efficiencies are obtained by maintaining high motive pressures rather than by wasteful throttling. Summary & Results: The McGuinness distillation system is a practical demonstration of the principle of thermal recompression. The high pressure steam passing through the thermocompressor captures the heat (in the form of steam vapor) that would otherwise be lost. This becomes Kinetic energy of such magnitude that a substantial quantity of low pressure steam is recovered and compressed for reuse in the beer column. Our Croll Reynolds system resulted in a 25% reduction in live steam demand and provided us with a maintenance free system with a less than two year payback. It has been our most practical system for reducing overall production and energy costs.