Use these guidelines to improve the performance of steam jet water chillers and find hidden savings in your plant: For large, continuous flows of chilled water for a process plant, there is no more simple or reliable technology than the steam jet ejector (SJE) water chiller, often referred to as a steam jet refrigeration plant. It has no moving parts, requires little maintenance and can handle huge water flowrates – up to 6,500 gal/min. Thousands of manufacturing facilities around the world rely on SJE water chillers for critical services. These include paper mills, and chemical and petrochemical process plants, where steam is available. In the pulp and paper industry, SJE water chillers are commonly used to chill massive quantities of water for bleaching operations.

Because SJE water chillers are reliable and provide many years of rugged service, facilities tend to forget that these systems require routine maintenance. Such activities can be as simple as performing periodic inspections or installing instrumentation to monitor the plant behavior. Further, as facilities seek to improve efficiency, they need to examine and possibly upgrade their chillers to achieve optimum effectiveness. Chilled water demand may change after a number of years, and the chiller’s configuration and energy consumption can be tailored to suit the new demand.

Principles Of Operation: The SJE water chiller works on the principle of evaporative cooling. As a small amount of water is evaporated, the remaining body of water is cooled in accordance with thermodynamic principles. To cool water quickly to cold temperatures, the evaporation must be performed under vacuum. It is generally completed in a number of stages to improve energy efficiency, and there are normally between two and four chilling stages (Figure 1).

A typical SJE water chiller employs several “booster” ejectors, one or more per chilling stage. A booster is an ejector that operates before a condenser. The booster suction pulls a vacuum, evaporating water and entraining dissolved noncondensibles and leakage air, and then discharges into a condenser. As with any ejector, the booster uses positive-pressure motive steam to operate. The motive steam and water vapor are condensed by cooling water in a condenser, which itself must operate under a vacuum. It is imperative to maintain at least the design vacuum in this condenser. A two-stage steam jet vacuum set, often called an air-pump, is commonly used for this purpose. By evaporating an amount of water under vacuum, the first chilling stage cools the remaining water to an intermittent temperature, and each subsequent stage takes over until the final water temperature is reached. There are several possibilities for this process. For example, more than one condenser may be most efficient, or a shell-and-tube condenser may be the right selection, depending on site conditions.

Troubleshooting: A SJE water chiller needs little maintenance. But when it does malfunction, it is often difficult to find a solution to the problem. Over time, service conditions can change – the demand on the cooling-water supply may increase; the average temperature of the cooling water, especially in summer, may increase; an older boiler may have lost efficiency, been deaerated, or may have been replaced; different process demands may be placed on the steam supply; or more air may be leaking into the system. All these factors will gradually deteriorate the system’s performance.

The first thing to look at when troubleshooting a SJE water chiller is the vacuum established at the main condenser inlet (i.e., at the booster’s discharge). If this vacuum is very poor, the plant may cease to do any appreciable chilling, and in fact, under such conditions, the motive steam from the boosters can “backfire” and actually heat the water up. Even if the chiller does not completely malfunction due to poor vacuum, there is still a negative consequence since the pressure at the booster’s discharge will be above the design pressure. Thus, the boosters must be run at a higher motive steam pressure – possibly up to 30% higher than needed. The greater steam pressure requirement means greater steam consumption, which translates into wasted money.

Common Causes Of Problems: Most problems in a SJE water chiller are found to reside in the system that maintains vacuum in the main condenser. Vacuum systems can fail for a number of reasons. Some common causes of failure are described below:

Air leakage into the chiller – Air leaks often occur through joints or flanged connections, or through corroded or eroded parts. For instance, the discharge elbow of the booster can suffer erosion from the high-velocity steam and holes may develop in that position. The piping from the condenser down to the hotwell (also known as a barometric leg) is under vacuum and may be a source of air leakage as well, particularly since it is in contact with the potentially corrosive hotwell water.

A SJE water chiller is typically designed to allow for an air leakage rate of 50-75 lb/h. A hole measuring just a few millimeters in diameter will cause significant air leakage, which damages the vacuum, increases the booster discharge pressure, and consequently, increases the need for booster steam. More serious malfunctions may also result.

A blockage or pressure drop in the lines – A shifted gasket can cause a pressure drop in the vacuum set; or, if the final atmospheric discharge piping becomes blocked, it could result in a pressure drop that affects the entire vacuum set.

Insufficient steam pressure – Under normal conditions, an ejector needs its full design motive pressure to operate. In practice, an ejector works with steam that is fed at a pressure up to 10% below the design pressure of the ejector.

High-pressure steam – This can also be a problem, since running an ejector at a pressure substantially above the design pressure decreases capacity, mainly because of choking in the ejector throat. It is safe to run an ejector at a pressure of about 25% above its design pressure. At higher pressures, the steam to the ejector should be throttled back to a pressure that is closer to the design pressure.

Too much or too little superheat in the steam – Superheat in the steam will increase the steam’s specific volume. Since an ejector nozzle has a fixed orifice, more or less steam will be passed, depending on the degree of superheat. This can have the same effect as increasing or decreasing the motive steam pressure. Too little superheat is not normally a problem, unless the ejector was designed for a large degree of superheat.

Excessive moisture in the steam – Steam quality is an important factor, since wet steam alters performance of the ejector. It accelerates wear and tear on the system (e.g., changes critical dimensions on nozzles and venturis.

Cooling water to the barometric condenser – Hot water or too little cooling water will increase the pressure in the condenser. Too much cooling water may flood the condenser.

Worn-out equipment – Corroded equipment or equipment that is generally in bad condition can cause a system to fail. While the vacuum system is normally the cause of problems, the boosters may also lose efficiency, especially after years of steam erosion in the body and/or the steam nozzles. The chill tank and condenser are generally trouble-free, but should not be overlooked in the preventative-maintenance program.

Chiller Troubleshooting Checklist: When there is a noticeable change in the performance of a chiller, engineers may need troubleshooting assistance. Troubleshooting can be made more simple if it is approached systematically:

- Steam lines from the utility side should be well-insulated to prevent condensation. Insulation thickness is a function of steam temperature as well as pipe diameter.

- Install a steam separator before the chiller to ensure that the steam is dry. If steam quality is questionable, use a calorimeter to measure the percentage of moisture in the steam. The maximum allowable level of moisture in the steam is 3%.

- Check the steam pressure on each ejector to ensure that it is within limits. Checking the pressure of only the main steam line will not suffice.

- Water pressure should be within 15% of the design pressure.

- Water temperature should be at or below the design temperature.

- Water flowrate must be adequate for proper condensation and cooling. Usually a 15-30[degrees]F temperature rise over a condenser is acceptable, which is the difference between outlet and inlet water temperatures. If the temperature rise is higher than design, too little cooling water is being used. If the temperature rise is lower than design, too much cooling water is being used, which can lead to flooding (especially since the tailpipe tends to clog up with mineral deposits over time). It is good practice to operate within one or two degrees less than the condenser’s design temperature rise.

- Excessive air leakage, if any, may be calculated by doing a “drop test” as per the Heat Exchange Institute’s (HEI; Cleveland, OH; www.heatexchange.org) protocol. In this test, the air leakage is calculated based on system volume and time taken to build up pressure from vacuum after the ejectors are turned off.

- Inspect the system for eroded or corroded parts, especially the ejector nozzles, diffusers and condenser water nozzles. Check for cracked or worn parts.

- Check for clogs in nozzles, diffusers, strainer and barometric legs or the discharge piping to atmosphere.

- Check for clogged or fouled condenser tubes or condenser inlet nozzles.

- Check for steam leaks between the steam chest and nozzle, which will increase the suction load to the ejector.

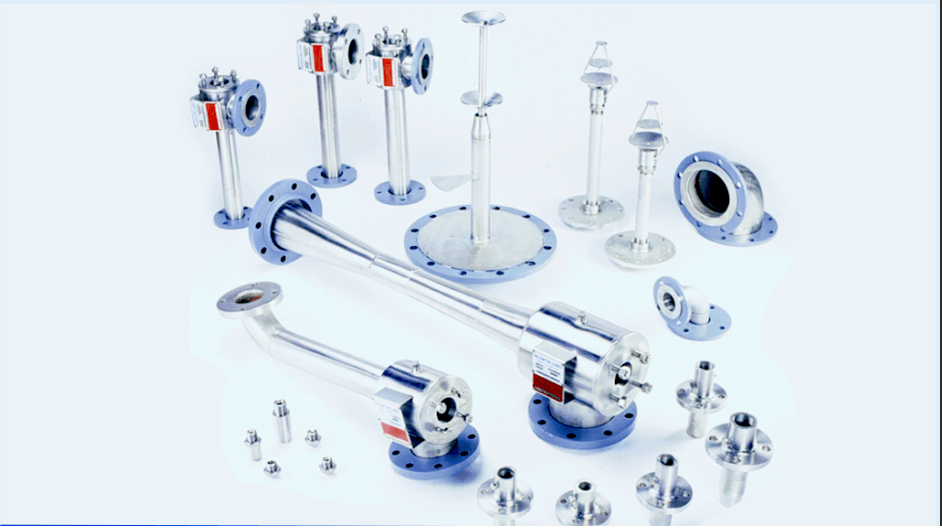

- Always keep spare parts on hand (Figure 2), including: one steam nozzle for every ejector-stage (or more for a multi-nozzle unit); spare ejectors for the vacuum set; at least one good vacuum gage (in absolute pressure units) for checking vacuum at various points in the plant.

- Although it is theoretically possible for the plant engineer to refurbish the parts described above, refurbishing is not generally recommended because the parts’ critical dimensions may differ from those in the original components. One may choose to discard and replace inexpensive parts, such as nozzles.

In a corrosive environment where parts replacement is frequent, stainless steel may be used in place of the original materials of construction (normally cast iron or steel).

Optimizing A Steam Jet Chiller: After many years of operation, a plant should reexamine its chilled water requirements, as well as the required final temperature of the chilled water. It is likely that the demand for chilled water has changed since the plant was originally designed and it may be possible to retrofit an existing chiller with boosters that are designed for the new requirement.

If the chilled water flowrate is less than the original design flowrate, the water outlet temperature will be colder than necessary. This may not seem like a concern, but colder water means wasted steam. Boosters with a lower capacity and lower steam consumption can be used to achieve the required temperature. Conversely, higher water flowrates and/or colder final temperatures may be obtained by retrofitting the plant with higher-capacity boosters.

There is a limit to how much a system can be retrofitted. One smart choice may be to install a new SJE water chiller to operate in series or parallel with the existing unit. One large Midwest papermill took this approach when it doubled its chilled water production to support an expanded chlorine dioxide plant that produced 35 ton/d of chlorine dioxide (Figure 3). An existing vacuum chiller was joined by a new SJE water chiller to cool 600 gal/min of water from 85[degrees]F to 45[degrees]F. At peak times, the two units operate in parallel. At off-peak times, the older unit is held on standby.

Steam Pressure Control: As mentioned earlier, when the condenser vacuum is not sufficient, the steam pressure required at the boosters becomes greater than required by design. The converse is also true: When vacuum is better than design, lower motive steam pressure is required at the boosters. When the plant is operating properly, the vacuum is usually better than design, aided by the fact that the air leakage rate to the plant is normally over-designed for safety, sometimes by as much as a factor of 50%, and because the cooling-water temperature is usually seasonally colder.

Steam pressure to the boosters may be throttled with control valves as a function of the absolute pressure at the booster discharge. As the pressure at the condenser changes, the steam pressure to the booster may be increased or decreased by automated control. For example, suppose a SJE water chiller is designed for a condenser pressure of 2.7 in. Hg, based on a cooling water temperature of 87[degrees]F and a steam pressure of 63 psig. During the colder months, the cooling water will bring the condenser pressure down to 1.5 in. Hg. Figure 4 shows that the steam pressure required to provide a booster discharge pressure of 1.5 in. Hg is about 35 psig. Thus, a plant can save approximately 40% of the steam consumption by throttling the steam pressure from 63 psig to 35 psig.

Figuring Out The Costs: The cost of steam is not easily measured, but accepted values range from $6-$ 10 per 1,000 lb of steam. An average-size SJE water chiller uses 20,000-30,000 lb/h steam and operates about 8,000 h/yr. Based on these parameters, the following estimates hold true:

- A vacuum leak or poor operating equipment may result in an extra steam requirement of 20%. The additional annual cost to the plant could be as much as $300,000/yr.

- Steam pressure control may reduce steam consumption by 20-40%, which translates into a savings of $200,000-$500,000/yr.

- A combination of retrofitting boosters for actual chilled water requirements, in addition to equipment repairs and steam pressure control, can save up to 60% of the steam.

Maintenance, troubleshooting and optimization of an existing SJE water chiller can provide important savings. To increase your plant’s bottom line, maximize the efficiency of the SJE water chillers. The plant will become more efficient.

By: Guy Levy, Production Manager – Croll Reynolds Co.