The Jari Project, the world’s most remote pulp and paper plant, began operation in Brazil in early 1978, utilizing a vacuum water chilling system for the bleaching operation. During the initial stages of pulp processing, a solution of chlorine dioxide and water is used to bleach the pulp. Greater concentrations of chlorine dioxide can be obtained if the water is chilled first. Because of the remote location of the Jari Project, the water chilling system had to be one that would operate reliably with little downtime and minimum maintenance.

A steam jet vacuum refrigeration system was selected for its advantages over mechanical refrigeration systems. It operates quietly, without moving parts; it requires almost no maintenance when compared with refrigeration systems that incorporated high-speed rotary or reciprocating compressors; it does not require chemical refrigerants or absorption solutions that might be a source of contamination, a storage problem or a frequent contributor to the fouling of the condenser tubing; specially trained personnel are not needed to maintain the system.

The Jari Project, the world’s most remote pulp and paper plant, began operation in Brazil in early 1978, utilizing a vacuum water chilling system for the bleaching operation. During the initial stages of pulp processing, a solution of chlorine dioxide and water is used to bleach the pulp. Greater concentrations of chlorine dioxide can be obtained if the water is chilled first. Because of the remote location of the Jari Project, the water chilling system had to be one that would operate reliably with little downtime and minimum maintenance.

A steam jet vacuum refrigeration system was selected for its advantages over mechanical refrigeration systems. It operates quietly, without moving parts; it requires almost no maintenance when compared with refrigeration systems that incorporated high-speed rotary or reciprocating compressors; it does not require chemical refrigerants or absorption solutions that might be a source of contamination, a storage problem or a frequent contributor to the fouling of the condenser tubing; specially trained personnel are not needed to maintain the system.

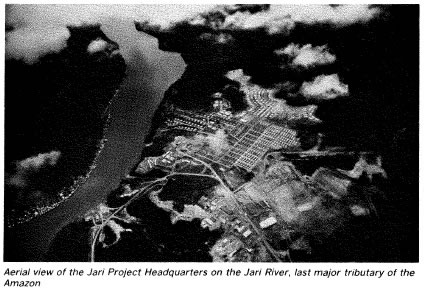

The pulp mill is accessible only by bush plane or an arduous boat excursion up the Amazon River. Unconventional aspects of this installation include its construction on two barges in Kure, Japan, its transport on a 15,000 mile, 93-day voyage west from Japan across the Indian and Atlantic Oceans, and its installation on a site some 250 miles inland on the Jari River, an Amazon tributary.

The key to the uniqueness of the operation is its integration within an almost completely self-sustaining environment. The Jari complex is comprised of a pulp mill, a city to handle the needs of some 10,000 employees and complete support facilities for food, water, electricity, housing and other necessities.

The degree of self-sustenance is evidenced by the fact that scrap pulp is utilized as the fuel source. Two large, wood-fired, high pressure power boilers provide energy, not only for the paper mill, but also for ancillary support functions.

The water chilling system installed at the Jari site is a freestanding, four-stage, steam-jet refrigeration unit with a rated capacity of 1400 tph (750 gpm). It was not deemed necessary to have the unit shipped to the construction site in Japan. Instead, it was shipped directly to the plant operating site where it was installed as part of the chemical system.

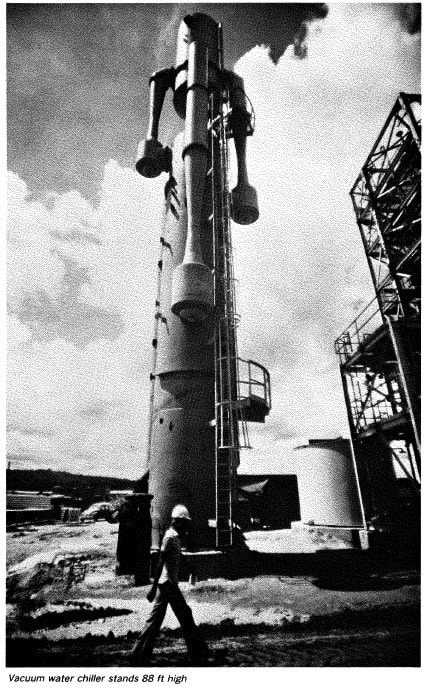

The self-supporting unit measures little more than 8′ in diam at its widest point. It stands 88′ high and incorporates an 8 ‘6″ barometric condenser mounted above an 8’ dia., four-stage chill tank. Vacuum for the chilling process is created by four large multi-nozzle booster ejectors.

Process water enters the vacuum refrigeration system and flows through a perforated weir plate where it is exposed to a vacuum. The water boils instantly as its vapor pressure reaches equilibrium with the vacuum maintained in the chamber. The heat of vaporization comes from the sensible heat of the water. The loss of this heat energy chills the water.

The water then flows through three additional chambers, each one at a lower absolute pressure, until the process water reaches design temperature in the final chamber. The chilled water is then pumped to the process from a reservoir in the base of the system.

Under maximum load conditions, water enters the chilling system at 86°F and is chilled to 40°F. The desired vacuum is maintained in each chamber of the chill tank by a separate 42″ multiple nozzle booster ejector that compresses water vapor from the vacuum in the chill tank to a slightly higher pressure in the overhead condenser. At this higher pressure, the vapor can be condensed by ambient cooling water. Noncondensables are removed from the condenser by a two-stage ejector air pump.

When a lower flow rate of chilled water is required for the operation, or when the process water enters the system at less than 86 ° F, the total tonnage or load is decreased. An automatic control system turns the steam on and off to one or more of the boosters serving each chill tank compartment. Chilled water automatically bypasses the inoperative compartment to avoid the addition of heat. The purpose of these controls is to maintain the chilled water temperature out of the system at 40°F when the load or tonnage fluctuates. Since the steam is turned on and off during this process, the total steam requirement is reduced. Steam savings are roughly proportional to the decrease in tonnage required. For a 30% decrease in tonnage, a savings of approximately 25-30% of the total steam usage can be realized. When controls are provided for all four boosters, there is no lower limit on the throttling capacity of the steam jet refrigeration system.

When the chilling system was first activated, it failed to operate. The manufacturer received an emergency call from Brazil just prior to the Jari Plant start-up. The system would not function properly. A technician was dispatched within a matter of hours to the site.

A quick visual check by the technician pin-pointed the problem. When the system was installed at the site, the first and second stages of the two-stage ejector systems were interchanged. As a result, the unit would not produce the required vacuum. The problem was easily corrected. The system was then started up smoothly and provided design chilled water immediately.

One of the benefits of the system is that it is almost impossible to hear in operation. The absence of mechanically operating parts means the system operates almost silently, without vibration.

With a service life of 40 years or more, the chilling unit is suited for outdoor installation and requires minimal ground area for installation. Maintenance costs are estimated to be less than $500 per annum. Once activated, the system requires little or no supervision. Latest reports from the Jari Plant indicate that all facets of this one-of-a-kind project are operating successfully.

By: CP Staff

The pulp mill is accessible only by bush plane or an arduous boat excursion up the Amazon River. Unconventional aspects of this installation include its construction on two barges in Kure, Japan, its transport on a 15,000 mile, 93-day voyage west from Japan across the Indian and Atlantic Oceans, and its installation on a site some 250 miles inland on the Jari River, an Amazon tributary.

The key to the uniqueness of the operation is its integration within an almost completely self-sustaining environment. The Jari complex is comprised of a pulp mill, a city to handle the needs of some 10,000 employees and complete support facilities for food, water, electricity, housing and other necessities.

The degree of self-sustenance is evidenced by the fact that scrap pulp is utilized as the fuel source. Two large, wood-fired, high pressure power boilers provide energy, not only for the paper mill, but also for ancillary support functions.

The water chilling system installed at the Jari site is a freestanding, four-stage, steam-jet refrigeration unit with a rated capacity of 1400 tph (750 gpm). It was not deemed necessary to have the unit shipped to the construction site in Japan. Instead, it was shipped directly to the plant operating site where it was installed as part of the chemical system.

The self-supporting unit measures little more than 8′ in diam at its widest point. It stands 88′ high and incorporates an 8 ‘6″ barometric condenser mounted above an 8’ dia., four-stage chill tank. Vacuum for the chilling process is created by four large multi-nozzle booster ejectors.

Process water enters the vacuum refrigeration system and flows through a perforated weir plate where it is exposed to a vacuum. The water boils instantly as its vapor pressure reaches equilibrium with the vacuum maintained in the chamber. The heat of vaporization comes from the sensible heat of the water. The loss of this heat energy chills the water.

The water then flows through three additional chambers, each one at a lower absolute pressure, until the process water reaches design temperature in the final chamber. The chilled water is then pumped to the process from a reservoir in the base of the system.

Under maximum load conditions, water enters the chilling system at 86°F and is chilled to 40°F. The desired vacuum is maintained in each chamber of the chill tank by a separate 42″ multiple nozzle booster ejector that compresses water vapor from the vacuum in the chill tank to a slightly higher pressure in the overhead condenser. At this higher pressure, the vapor can be condensed by ambient cooling water. Noncondensables are removed from the condenser by a two-stage ejector air pump.

When a lower flow rate of chilled water is required for the operation, or when the process water enters the system at less than 86 ° F, the total tonnage or load is decreased. An automatic control system turns the steam on and off to one or more of the boosters serving each chill tank compartment. Chilled water automatically bypasses the inoperative compartment to avoid the addition of heat. The purpose of these controls is to maintain the chilled water temperature out of the system at 40°F when the load or tonnage fluctuates. Since the steam is turned on and off during this process, the total steam requirement is reduced. Steam savings are roughly proportional to the decrease in tonnage required. For a 30% decrease in tonnage, a savings of approximately 25-30% of the total steam usage can be realized. When controls are provided for all four boosters, there is no lower limit on the throttling capacity of the steam jet refrigeration system.

When the chilling system was first activated, it failed to operate. The manufacturer received an emergency call from Brazil just prior to the Jari Plant start-up. The system would not function properly. A technician was dispatched within a matter of hours to the site.

A quick visual check by the technician pin-pointed the problem. When the system was installed at the site, the first and second stages of the two-stage ejector systems were interchanged. As a result, the unit would not produce the required vacuum. The problem was easily corrected. The system was then started up smoothly and provided design chilled water immediately.

One of the benefits of the system is that it is almost impossible to hear in operation. The absence of mechanically operating parts means the system operates almost silently, without vibration.

With a service life of 40 years or more, the chilling unit is suited for outdoor installation and requires minimal ground area for installation. Maintenance costs are estimated to be less than $500 per annum. Once activated, the system requires little or no supervision. Latest reports from the Jari Plant indicate that all facets of this one-of-a-kind project are operating successfully.

By: CP Staff