Are you interested in learning more about low-pressure ejectors and their flow characteristics? This blog post explores the science behind how these systems operate to provide an exciting, useful look at an often-overlooked technology. We’ll cover how the ejector core works, discuss typical pressure ratios as well as recommendations for sizing selection and installation considerations. Plus, we’ll explain why understanding this information is essential to creating optimal performance in your system. So read on to find out more about the principles of low-pressure ejectors and what they can do for us.

What is a low-pressure ejector installation and why should you care about it

A low-pressure ejector installation is a great way to reduce energy costs associated with your everyday activities. By installing one, you can enjoy more efficient air and liquid movement in your home or business, which not only helps you save money but can also improve the overall living environment.

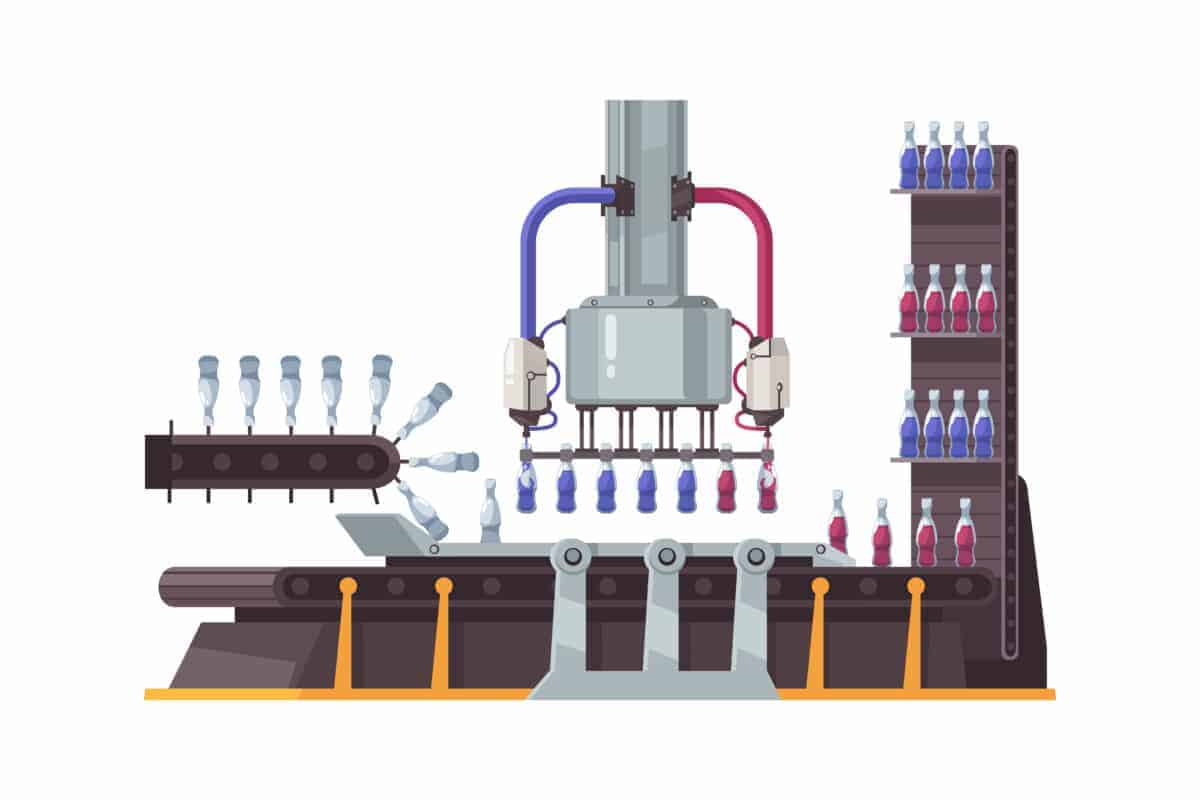

A jet ejector pump installation is a setup that replaces traditional mechanical pumps with jet pumps that use low-pressure energy and compressed air. The jet ejector pumps work by using differential pressures which results in a huge cost saving when compared to more traditional methods. With jet ejector pumps, your energy use can be much more efficient while still being able to handle large, long-term cooling or heating requirements. They are particularly useful for exhausting contaminated air from areas like kitchens and bathrooms and for removing liquid residue from commercial work areas.

With an efficient setup, these tasks can be performed much quicker and with a fraction of the power that would traditionally be needed. All in all, low-pressure ejectors are an excellent choice when it comes to modernizing any residential or commercial space while saving money at the same time.

Physical properties of a low-pressure ejector installation

The physical properties of a low-pressure ejector installation mean that it is an incredibly versatile and valuable way to control the flow of industrial process materials. The use of venturi effects in the vacuum mixing tube allows for a wide range of pressures and temperatures, with the ability to accurately regulate the strength and direction of each stream.

Due to this versatility, it has become widely used for many applications including distillation, crystallization, particle size separation, filtration, and other processes. The construction is also designed for maximum durability and dependability, as well as cost efficiency when compared to other conventional methods. All these factors make low-pressure ejector installation an invaluable tool in modern industry.

Different flow patterns in a low-pressure ejector installation

Jet ejector pumps are a popular solution for low-pressure systems as they offer increased efficiency compared to traditional jet pumps. But these jet ejector pumps require careful attention to the flow pattern for optimal performance. Operating jet ejector installations with the wrong flow patterns can cause serious damage, which would be costly to correct.

Essentially, jet ejectors rely on two different flows; one “jet” of high-velocity liquid enters a low-pressure zone and creates an area of low pressure that draws in another stream from the system. If this jet flow is inadequate or misdirected, it will result in reduced performance of the jet pump installation. Therefore, it is important for installers to thoroughly assess the flow patterns of jet ejectors to ensure peak outputs in terms of both energy and productivity.

Importance of pressure ratios for the efficient functioning of an ejector system

Pressure ratios are a critical component to consider when designing an efficient ejector system. Three pressure ratios, condensation ratio, compression ratio, and expansion ratio combine to ensure the best results in terms of energy efficiency.

Quite simply a higher pressure ratio means that the incoming pressure is greater than the exhaust pressure, resulting in more energy being extracted from the exiting steam. Additionally, optimizing a system’s pressure ratios can lead to increased capacity while simultaneously reducing leakage. Pressure ratios have a major impact on how well an ejector system performs and any professional needs to be aware of the importance of choosing the correct values for each of those three components before moving forward with installation or repairs.

Effect of various parameters on the flow characteristics within an ejector system

When studying the flow characteristics of an ejector system, it is important to consider various parameters. These include the jet pressure ratio, the nozzle design, and the differences in gas density. Examining each variable separately can help understand their relative importance on the overall system performance. Furthermore, it is possible to assess the effect of combinations of different parameters to determine their synergistic or interactive effects on the system operation. Using this data effectively can make all the difference in optimizing efficiency or mitigating any possible losses from within an ejector system.

How to optimize the flow characteristics in a low-pressure ejector installation for an efficient operation

- One of the most effective ways to optimize the flow characteristics in a low-pressure jet ejector installation is through the use of proper system design. Doing so will ensure better performance and efficient operation for longer periods.

- Careful attention should be given to fluid velocity, jet/diffuser area ratios, jet-to-diffuser ramp distance, jet-to-diffuser taper angles, and any other related components when designing an effective jet ejector pump installation.

- Additionally, regular maintenance and inspection must be done on a timely basis as this will allow for the detection of any potential problems or inefficiencies before they become more serious.

All these measures will contribute to a high-functioning jet ejector system with optimal flow characteristics.

Thus, we’ve seen how a low-pressure ejector installation can provide numerous advantages for homeowners and businesses alike. Do remember, however, that its efficient functioning is wholly dependent on the pressure ratio between the motive and suction flow. Also, make sure to assess the effect of various factors like the number of stages or diameter on the flow parameters within an ejector system to garner optimized performance. So go ahead, get in line with all the savvy people out there, and be prepared for maximum efficiency with your low-pressure ejector system.

Get in touch with us

Related Posts

Understand the Working Principle of a Steam Ejector or Injector System

How Steam Ejectors Work: The Ultimate Guide

About Us

Croll Reynolds Company, Inc. is a US-based engineering firm specializing in the design, and manufacture of process vacuum systems and related equipment.