You probably don’t think about air ejectors very often, but they play a big role in many industries. From manufacturing to food processing, air ejectors are used to helping move materials around. But how do they work? Let’s take a closer look!

What is an air ejector and how does it work

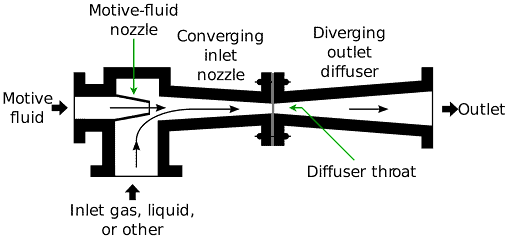

An air ejector is a device that uses the power of pneumatic suction to draw in and expel gas or particulate matter. It’s typically used when an environment needs to be vacuumed to control the pressure inside.

At its simplest, it works by sucking air through a nozzle which causes the combustible material to be ejected forcefully into a vessel or chamber. If you’ve ever seen an action movie where someone opens up a long tube and shoots something out, chances are they were using an air ejector! Pretty cool, huh?

The benefits of using an air ejector

When it comes to individual or industry-wide projects, an air ejector is one of the most convenient tools to have in your arsenal. It’s able to deliver instant vacuum action utilizing only compressed air as a power source, making it incredibly efficient and easy to use.

This handy device can be used in endless scenarios, from taking liquids out of containers to producing a strong airflow needed to blow away sawdust. The reliable air suction helps ensure your project remains as mess-free as possible and that you’re doing the best work you can!

How to choose the right air ejector for your needs

It’s not always an easy decision to make, but if you want to figure out which air ejector is best for your needs, you have a few things to consider. First off, it’s important to remember the difference between eductors and ejectors: eductors move fluids by using a device that sucks in the fluid through the nozzle, while ejectors use suction created by steam or high-pressure air to do the same job.

Knowing what kind of pressure your application requires can help narrow down your choices significantly. Of course, you’ll also want to make sure it matches up with any existing machinery or infrastructure you may have, like tubing or filtration systems.

Also, it’s important to consider what kind of features you need and how much room you have. Do you need an ejector with a large capacity? An adjustable outlet pressure range? Or something easy to install and operate?

Researching the different models available can help you find the perfect fit for your needs. Whether it’s a single stage or dual stage, horizontal or vertical, don’t leave yourself feeling deflated! Take your time and find the best air ejector for you.

Tips for using an air ejector effectively

Air ejectors can be a great way to save energy and increase productivity! To make the most of this awesome technology, it’s important to keep things in good working order:

- Start by making sure your air ejector is clean and properly maintained.

- Monitor air pressure and temperature, so you have the optimal working environment for your machine.

- Adjust the flow rate according to the job you are doing and analyze any changes that occur when using an air ejector, since they allow finer control with different materials.

- Utilize preventative maintenance regularly to ensure equipment is properly serviced before it even needs it!

With these tips in hand, you’re ready to use your air ejector like a total pro!

Troubleshooting common problems with air ejectors

Successfully troubleshooting common problems with air ejectors can be a tricky challenge, but if you’re feeling adventurous and up for the task, it can also be quite fun.

Ensuring that your equipment is in working order and all components are functioning properly will save you time and energy down the line. Also, diagnose your system to find out what may be causing unexpected issues and do the work necessary to fix them right away.

Sure, it may seem daunting at first, but you’ll get a sense of satisfaction once everything is operational. The next time an issue arises with an air ejector, you’ll feel more confident that you can handle it like a pro!

Conclusion

If you’re looking for a way to move large amounts of air with relatively little energy, an air ejector is a right tool for the job. These devices have many benefits and can be used in a variety of settings – but only if you choose the right model and use it properly. By following the tips in this blog post, you can ensure that your air ejector will serve you well for years to come.

Get in touch with us

Related Posts

Understand the Working Principle of a Steam Ejector or Injector System

How Steam Ejectors Work: The Ultimate Guide

About Us

Croll Reynolds Company, Inc. is a US-based engineering firm specializing in the design, and manufacture of process vacuum systems and related equipment.