If you ask an engineer why they prefer to use steam rather than air as a working fluid in an ejector, the chances are they’ll say it’s because air is structurally weak compared to water. While that’s true, there’s another reason: steam is a much better heat conductor than air. So not only is steam less likely to cause damage to the equipment, but it can also transfer heat more effectively. That makes it an ideal choice for many industrial applications. This blog will explore why steam is a better choice than air for an ejector so keep reading to find out more.

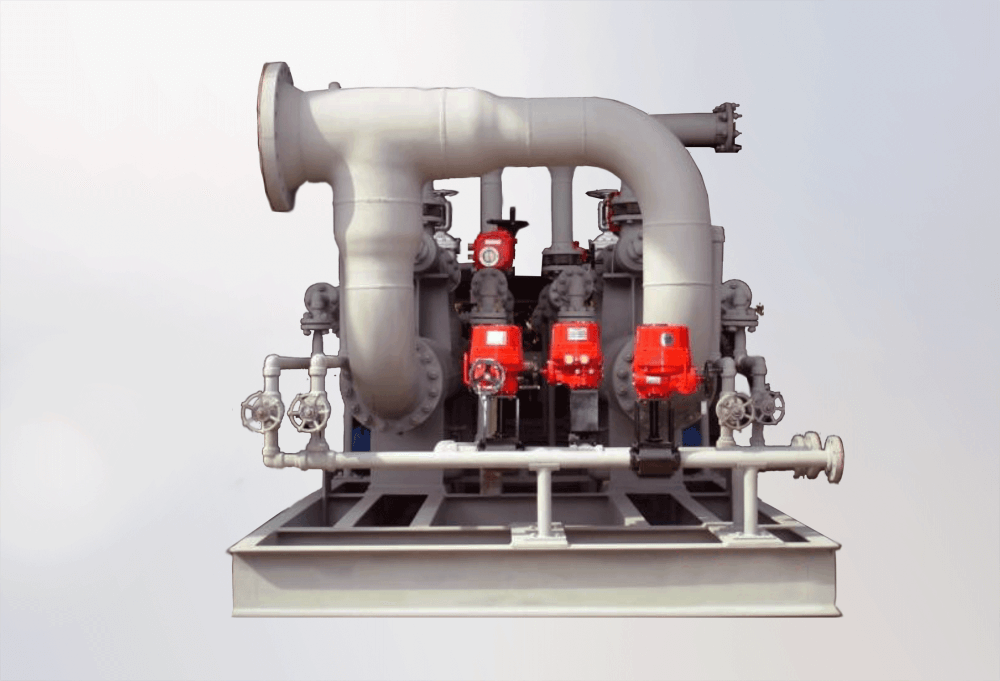

An ejector is a mechanical device that uses a working fluid to generate suction or pressure by converting the kinetic energy of the fluid. Ejectors are used in a variety of applications, including cooling systems, vacuum pumps and compressors. In essence, an ejector works by forcing high-pressure fluid into a nozzle that creates a low-pressure zone downstream. This low-pressure zone is then used to draw in and compress a second fluid, thus creating suction or pressure. Steam is the most common working fluid used in ejectors due to its favorable properties.

Steam can be used to create a vacuum

Steam is a powerful tool for not only cleaning but creating vacuums as well! Ejectors, or steam ejectors, are one of the most common ways of creating a vacuum with steam. Generally, ejectors make use of a high-pressure steam nozzle that ejects a high-velocity stream of steam combining it with another gas to form a low-pressure mixture. This mixture then expands and produces a region at low pressure, allowing the ejector to suck out ambient atmosphere and create the necessary vacuum. It’s really amazing to realize just how many possibilities exist when using steam – even something as unlikely as creating vacuums!

Air is structurally weak compared to water

Take a deep breath and suspend disbelief– did you know that air in our atmosphere is structurally weak compared to water? It’s hard to imagine why one of the four elements which make up everything on earth would appear so fragile, but ejectors show us this fundamental truth.

From ejector jets propelling planes thousands of miles in the air to rocket launches taking humans into space, ejectors are devices that use the power of pressure differences between gas and water particles to move forward what could otherwise remain motionless.

Even with the incredible force they rely on, ejectors help us recognize how much weaker gas particles are than those found in water! With this knowledge, let us appreciate the many wonderful accomplishments we achieved with an element so seemingly ordinary.

Water can be heated to a higher temperature than air

Water can be heated to a higher temperature than air, making it the perfect companion for ejectors which rely on the power of hot steam. It’s incredible how much potential water has when put to good use! Keeping this fact in mind can help us think of ways to make the most of hot water and use ejectors for a number of helpful tasks, from powering machinery in industries to driving turbines or providing energy. Hot water is an inherently powerful resource and, when utilized efficiently, may open up even more opportunities than we never thought possible.

Steam is more efficient than air in moving heat

From baking bread to making coffee, steam has been a staple in everyday life for centuries. It’s no wonder that industries have adapted this easy-to-use technology for their lateral heat transfer needs as well. Steam is an incredibly effective and efficient method of changing the temperature of a product quickly and uniformly from one area to another because it is made up of tiny molecules. These molecules are much smaller than air particles, which allows them to move heat more efficiently throughout the system. And when it comes to moving heat efficiently, few solutions beat steam!

Air can cause corrosion

Thanks to modern ejector technology, warm and moist air has become much less of a problem when it comes to corrosion. This means that industries that rely on pieces of machinery being exposed to air have been given a sort of shield against corrosion.

Ejectors work the same way an air conditioner does: by moving air around, the ejector creates small ejectosols which absorb and neutralize humidity in the air, thereby protecting from corrosion. Studies have shown that using an ejector can reduce the corrosion caused by natural processes by as much as 90%, allowing us to proudly use these tools across all sorts of industries.

All in all, steam has some significant advantages over air when it comes to transferring heat. With that said, each type of fluid has its own set of benefits and drawbacks that must be considered before making a decision. It is important to consult with a qualified engineer to determine which medium will work best for your specific application.

Get in touch with us

Related Posts

Understand the Working Principle of a Steam Ejector or Injector System

How Steam Ejectors Work: The Ultimate Guide

About Us

Croll Reynolds Company, Inc. is a US-based engineering firm specializing in the design, and manufacture of process vacuum systems and related equipment.