With the rising costs of utilities, Crystals International, Inc. (Plant City, Fla.), a producer of freeze-dried products for the chemical process industries (CPI), was exploring various methods to reduce energy consumption. For years, the firm had been concerned about energy costs, considering that dehydration is energy- intensive, with natural gas a major item in overhead expenses. The gas is used to fire boilers and provide steam to operate jet ejectors supplied by Croll Reynolds (N.J.), which in turn supply the vacuum for the dehydration process.

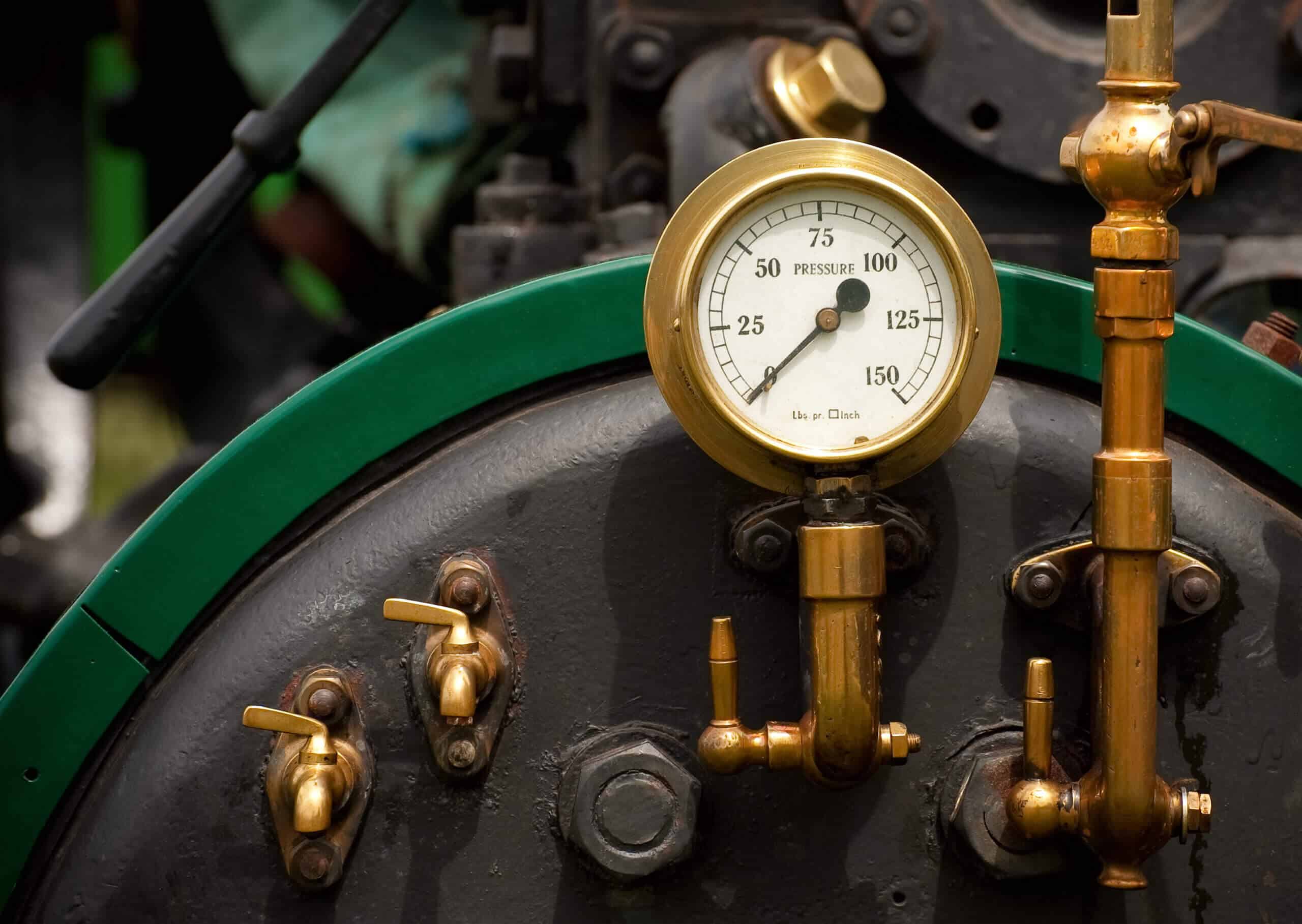

In efforts to increase efficiency and save money, Crystals International decided to replace two older boilers with a single, high-capacity unit. Producing 13,800 lb/h of 200-psig steam, the unit’s main purpose was to supply the plant’s two steam ejectors and a variety of other process needs. However, with the new boiler, system pressure would be increased and the ejector nozzles would see steam at 150 psig. This was a problem since the nozzles were designed to operate at 115-psig steam.

Since the internal dimensions were fixed, the steam ejector was designed for just one specific steam condition, and must operate near that condition for maximum efficiency. Operating at 150 psig with nozzles designed for 115 psig would be wasteful, increasing steam consumption by an estimated 26%, and possibly causing adverse effects on ejector operation.

To solve the problem, a pressure reducer, placed before the steam reached the nozzles was considered. However, Crystals International determined that reducing pressure promoted formation of potentially damaging condensate. The only alternative then, was to redesign the ejectors to accept the new system parameters.

Conferring with Croll Reynolds, Crystals International discovered that renozzling the existing ejector system to meet the new steam condition was economically feasible and advantageous. Based on steam savings of2,200 lb/h ( 150 psi) and natural gas costs of $0.36/100,000 Btu, savings for the two ejectors were estimated at about $240/d, or more than $62,000/yr based on a five-day week. With capital costs of the changeout estimated at $26,000, payout would come in just 21 weeks.

A seven-day operation made the bottom line look even more attractive. Annual savings would top $87,000, with payout in less than 16 weeks.

Redesign Underway: Crystals International decided to begin by renozzling one unit, and running it for 90 days to evaluate savings and system operation. After the trial period was completed, the firm deemed it a success, with the savings and payback period matching its earlier estimations. The company plans on renozzling the second ejector later this year.

With the new boiler installed and the first ejector renozzled, plant engineers undertook several related modifications. First, a steam flowmeter was installed to monitor steam flow and aid in verifying cost savings. Steam traps were also installed on the copper defrost lines for both dryer vacuum systems, with expectations of saving $15,000/yr.

At the same time, boiler feedwater temperature was raised from 125’F to 195’F by manipulating the continuous blowdown system. This resulted in an improvement on total heat load. Based on steam use of 10,000 lb/h, savings of 700,000 Btu/h, or nearly $16,000/yr on a five-day operation are expected.

In the future, plant engineers expect to add a Croll Reynolds-supplied heat exchanger to each ejector. Heat saved through this system will be used to raise boiler feedwater temperature, providing further energy savings for the operation.

By Jack B. Welch, Crystals InternationaL Inc.

To solve the problem, a pressure reducer, placed before the steam reached the nozzles was considered. However, Crystals International determined that reducing pressure promoted formation of potentially damaging condensate. The only alternative then, was to redesign the ejectors to accept the new system parameters.

Conferring with Croll Reynolds, Crystals International discovered that renozzling the existing ejector system to meet the new steam condition was economically feasible and advantageous. Based on steam savings of2,200 lb/h ( 150 psi) and natural gas costs of $0.36/100,000 Btu, savings for the two ejectors were estimated at about $240/d, or more than $62,000/yr based on a five-day week. With capital costs of the changeout estimated at $26,000, payout would come in just 21 weeks.

A seven-day operation made the bottom line look even more attractive. Annual savings would top $87,000, with payout in less than 16 weeks.

Redesign Underway: Crystals International decided to begin by renozzling one unit, and running it for 90 days to evaluate savings and system operation. After the trial period was completed, the firm deemed it a success, with the savings and payback period matching its earlier estimations. The company plans on renozzling the second ejector later this year.

With the new boiler installed and the first ejector renozzled, plant engineers undertook several related modifications. First, a steam flowmeter was installed to monitor steam flow and aid in verifying cost savings. Steam traps were also installed on the copper defrost lines for both dryer vacuum systems, with expectations of saving $15,000/yr.

At the same time, boiler feedwater temperature was raised from 125’F to 195’F by manipulating the continuous blowdown system. This resulted in an improvement on total heat load. Based on steam use of 10,000 lb/h, savings of 700,000 Btu/h, or nearly $16,000/yr on a five-day operation are expected.

In the future, plant engineers expect to add a Croll Reynolds-supplied heat exchanger to each ejector. Heat saved through this system will be used to raise boiler feedwater temperature, providing further energy savings for the operation.

By Jack B. Welch, Crystals InternationaL Inc.

To solve the problem, a pressure reducer, placed before the steam reached the nozzles was considered. However, Crystals International determined that reducing pressure promoted formation of potentially damaging condensate. The only alternative then, was to redesign the ejectors to accept the new system parameters.

Conferring with Croll Reynolds, Crystals International discovered that renozzling the existing ejector system to meet the new steam condition was economically feasible and advantageous. Based on steam savings of2,200 lb/h ( 150 psi) and natural gas costs of $0.36/100,000 Btu, savings for the two ejectors were estimated at about $240/d, or more than $62,000/yr based on a five-day week. With capital costs of the changeout estimated at $26,000, payout would come in just 21 weeks.

A seven-day operation made the bottom line look even more attractive. Annual savings would top $87,000, with payout in less than 16 weeks.

Redesign Underway: Crystals International decided to begin by renozzling one unit, and running it for 90 days to evaluate savings and system operation. After the trial period was completed, the firm deemed it a success, with the savings and payback period matching its earlier estimations. The company plans on renozzling the second ejector later this year.

With the new boiler installed and the first ejector renozzled, plant engineers undertook several related modifications. First, a steam flowmeter was installed to monitor steam flow and aid in verifying cost savings. Steam traps were also installed on the copper defrost lines for both dryer vacuum systems, with expectations of saving $15,000/yr.

At the same time, boiler feedwater temperature was raised from 125’F to 195’F by manipulating the continuous blowdown system. This resulted in an improvement on total heat load. Based on steam use of 10,000 lb/h, savings of 700,000 Btu/h, or nearly $16,000/yr on a five-day operation are expected.

In the future, plant engineers expect to add a Croll Reynolds-supplied heat exchanger to each ejector. Heat saved through this system will be used to raise boiler feedwater temperature, providing further energy savings for the operation.

By Jack B. Welch, Crystals InternationaL Inc.

To solve the problem, a pressure reducer, placed before the steam reached the nozzles was considered. However, Crystals International determined that reducing pressure promoted formation of potentially damaging condensate. The only alternative then, was to redesign the ejectors to accept the new system parameters.

Conferring with Croll Reynolds, Crystals International discovered that renozzling the existing ejector system to meet the new steam condition was economically feasible and advantageous. Based on steam savings of2,200 lb/h ( 150 psi) and natural gas costs of $0.36/100,000 Btu, savings for the two ejectors were estimated at about $240/d, or more than $62,000/yr based on a five-day week. With capital costs of the changeout estimated at $26,000, payout would come in just 21 weeks.

A seven-day operation made the bottom line look even more attractive. Annual savings would top $87,000, with payout in less than 16 weeks.

Redesign Underway: Crystals International decided to begin by renozzling one unit, and running it for 90 days to evaluate savings and system operation. After the trial period was completed, the firm deemed it a success, with the savings and payback period matching its earlier estimations. The company plans on renozzling the second ejector later this year.

With the new boiler installed and the first ejector renozzled, plant engineers undertook several related modifications. First, a steam flowmeter was installed to monitor steam flow and aid in verifying cost savings. Steam traps were also installed on the copper defrost lines for both dryer vacuum systems, with expectations of saving $15,000/yr.

At the same time, boiler feedwater temperature was raised from 125’F to 195’F by manipulating the continuous blowdown system. This resulted in an improvement on total heat load. Based on steam use of 10,000 lb/h, savings of 700,000 Btu/h, or nearly $16,000/yr on a five-day operation are expected.

In the future, plant engineers expect to add a Croll Reynolds-supplied heat exchanger to each ejector. Heat saved through this system will be used to raise boiler feedwater temperature, providing further energy savings for the operation.

By Jack B. Welch, Crystals InternationaL Inc.