Increased demand by tobacco product manufacturers for efficiency carrying out various production steps in meeting constantly expanding sales has resulted in a number of inventions that have completely displaced the older, less accurate and more costly methods.

MOISTURIZATION:

Moisturizing Tobacco with a Vacuum System A Quarter Century of Vacuum Processing At R.J. Reynolds Tobacco Company

Increased demand by tobacco product manufacturers for efficiency carrying out various production steps in meeting constantly expanding sales has resulted in a number of inventions that have completely displaced the older, less accurate and more costly methods.

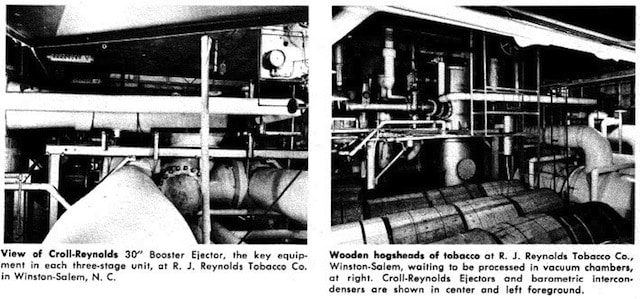

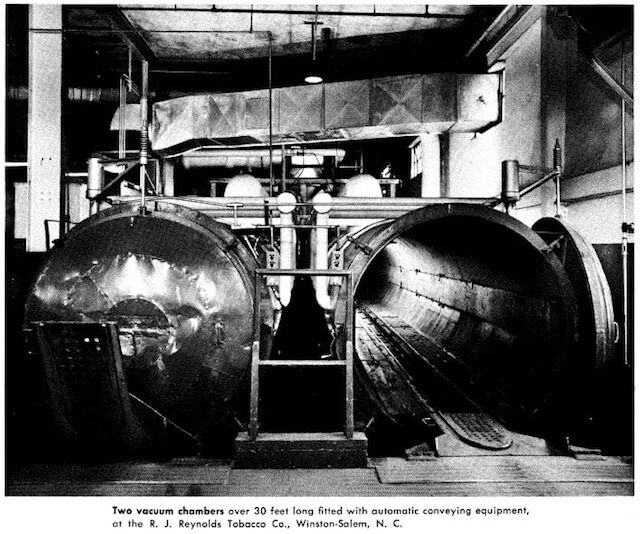

Moisturizing, an essential step in tobacco processing, has been no exception in the search for efficiency and better products. This process has come a long way from the “sweat room” of the 30’s, which, although sufficient for that time, is no match for the billions of uniform high quality cigarettes sold yearly today. Progress in Vacuum Moisturizing Equipment: The sweat room has been all but replaced by vacuum moisturizing equipment, and the process has been one of the most durable, maintenance-free installations in the industry. Before vacuum moisturizing, hogsheads of dry tobacco weighing approximately 1,000 pounds and containing only 10 to 12 percent moisture were placed in large sheds and subjected to high temperature and high humidity for two to three weeks. At best, this method would only add seven to eight pounds of moisture to each hogshead, and, due to the tightness of packing, the moisture would be concentrated near the edges of the contents. Consequently, stems and interior tobacco would still be excessively dry and brittle, causing great waste during further processing. Steam Jet Vacuum System Installed: For example, in 1936, R. J. Reynolds Tobacco Company of Winston-Salem, N. C., installed a steam jet vacuum system designed to moisturize the tobacco by first removing most of the air in the hogshead and then introducing steam to fill the vacuum. The process evenly and completely moisturizes the tobacco, making it pliable and less subject to breaking into unusable fines. Steam Provided By Vacuum Pumps: The vacuum required for full penetration of moisture from steam is provided by simple and economical steam jet vacuum pumps. On the original, and on other installations in 1937 and 1938, steam jet Evactors, manufactured by Croll Reynolds Co., Inc., were used. The Evactors are three-stage models. They pull vacuum from atmospheric pressure of 30″ mercury down to 0.2″, or better than 99 percent perfect, assuring maximum penetration of steam. From four to 30 hogsheads are placed in any of the four units using Croll Reynolds steam jets, and the vacuum chamber is sealed. The three booster jets operate sequentially, drawing off nearly all of the air in each of the hogsheads. When the desired vacuum is attained, low pressure saturated steam is admitted to the chamber. So effective is the vacuum that steam penetrates even the thick, woody stems of the tobacco leaf. Evactors Draw Vacuum: After the initial steaming, the Croll Reynolds Evactors are again used to draw another vacuum. The process may be repeated as many as three times, depending on the original moisture content of the hogshead. It adds as much as 25 pounds of moisture to a single hogshead – four times as much as the sweat room method, and much faster. Each complete cycle, including loading and unloading, takes 20 to 30 minutes. The steam jet installation has the combined advantage of operating without moving parts, and of being actuated by only 100 pounds pressure of dry steam. The system is completely automatic. The 1936, 1937 and 1938 installations are still in uninterrupted service with no maintenance necessary to the steam jets other than periodic cleaning of the nozzles. Through use of the system, the Reynolds Tobacco Company has been able substantially to improve speed and product quality, while lowering costs.