Jet Syphon

Jet Syphon

Pump liquids and semi-solid mixtures from vessels and sumps

About

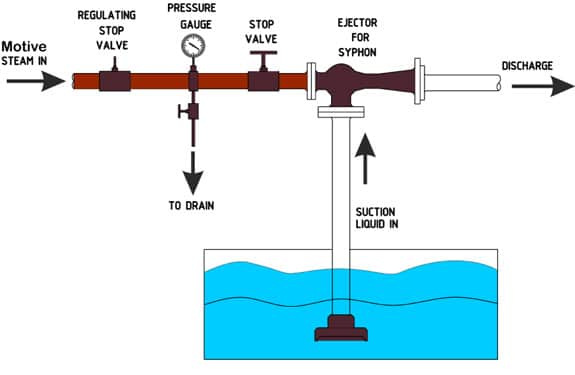

Syphons are similar in construction to a standard steam jet ejector; however, the suction fluid in a syphon is a liquid (usually water) instead of a gas or vapor. Syphons can utilize any type of condensable vapor but non condensable, dry-air motivated units are not generally recommended due to potential air/water hammer inside the syphon. This equipment is primarily used to pump sumps but can be designed to drain any vessel while transporting a process liquid. Syphons can be installed inline or elevated above a reservoir at any orientation. When discharging water at atmospheric pressure a syphon can generate a suction lift of up to 30-32 feet (around 10 meters). A syphon can be lowered down into a pit to take a higher-pressure differential at discharge head rather than suction lift.

In a Syphon, motive steam is used to increase the pressure of the process liquid. Since motive steam condenses in the fluid, there is also a measurable temperature rise across the unit. Syphons are commonly designed for minimal steam infusion but can be used as effective heaters if pressure increase across the unit is required but it is. In designing a syphon, care must be taken to ensure that all the motive steam condenses in the water, and that the water doesn’t boil inside the syphon.

Advantages

- Efficient lifting and transportation of liquid

- Low initial cost with minimal maintenance

- Ease of operation

- Heavy duty construction

- No special pipe supporting required

- In-line installation

- Quiet operation

- No moving parts or packing glands

- Can be constructed from a wide variety of materials

A syphon operates using the same principle as steam ejectors. High pressure steam passing through a converging-diverging motive nozzle converts motive energy to supersonic velocities and momentum. The supersonic velocity steam expanded through the motive nozzle creates vacuum which lifts, entrains, and transport it downstream of the syphon. The elevation of the unit is directly proportional to the ambient temperature of the liquid and its vapor pressure. The vacuum created for lifting can’t exceed the vapor pressure of the liquid after mixing with the motive steam.

- Chemical –product distillation, drying, flash cooling and more

- Oil and Gas – refinery processes, product distillation and more

- Food and Beverage – product crystallization, evaporation and more

- Water Treatment and Desalinization – product crystallization, evaporation and more