Tobacco

Moisturization:

Moisturizing Tobacco with a Vacuum System A Quarter Century of Vacuum Processing At R.J. Reynolds Tobacco Company

Increased demand by tobacco product manufacturers for efficiency carrying out various production steps in meeting constantly expanding sales has resulted in a number of inventions that have completely displaced the older, less accurate and more costly methods.

Moisturizing, an essential step in tobacco processing, has been no exception in the search for efficiency and better products. This process has come a long way from the “sweat room” of the 30’s, which, although sufficient for that time, is no match for the billions of uniform high quality cigarettes sold yearly today.

Progress in Vacuum Moisturizing Equipment: The sweat room has been all but replaced by vacuum moisturizing equipment, and the process has been one of the most durable, maintenance-free installations in the industry.

Before vacuum moisturizing, hogsheads of dry tobacco weighing approximately 1,000 pounds and containing only 10 to 12 percent moisture were placed in large sheds and subjected to high temperature and high humidity for two to three weeks. At best, this method would only add seven to eight pounds of moisture to each hogshead, and, due to the tightness of packing, the moisture would be concentrated near the edges of the contents. Consequently, stems and interior tobacco would still be excessively dry and brittle, causing great waste during further processing.

Steam Jet Vacuum System Installed: For example, in 1936, R. J. Reynolds Tobacco Company of Winston-Salem, N. C., installed a steam jet vacuum system designed to moisturize the tobacco by first removing most of the air in the hogshead and then introducing steam to fill the vacuum. The process evenly and completely moisturizes the tobacco, making it pliable and less subject to breaking into unusable fines.

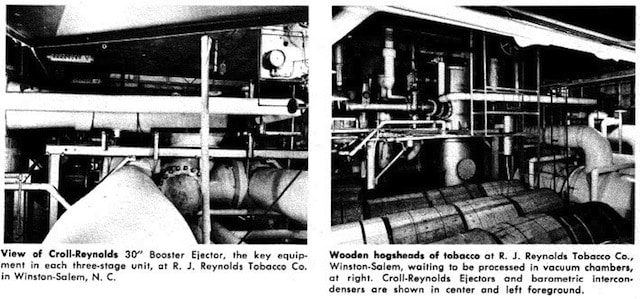

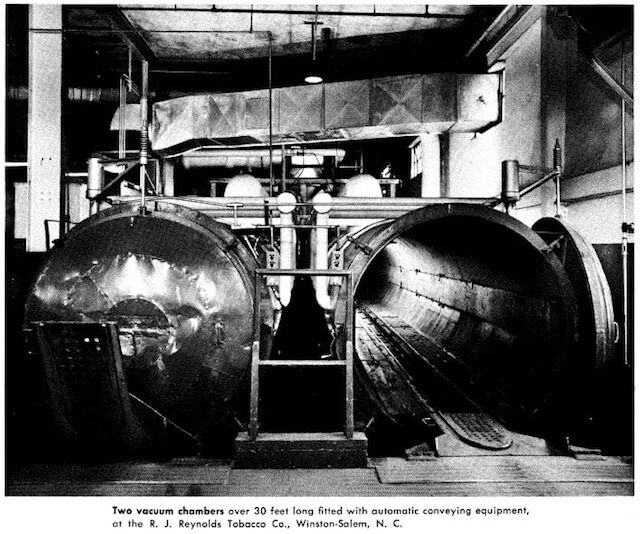

Steam Provided By Vacuum Pumps: The vacuum required for full penetration of moisture from steam is provided by simple and economical steam jet vacuum pumps. On the original, and on other installations in 1937 and 1938, steam jet Evactors, manufactured by Croll Reynolds Co., Inc., were used.

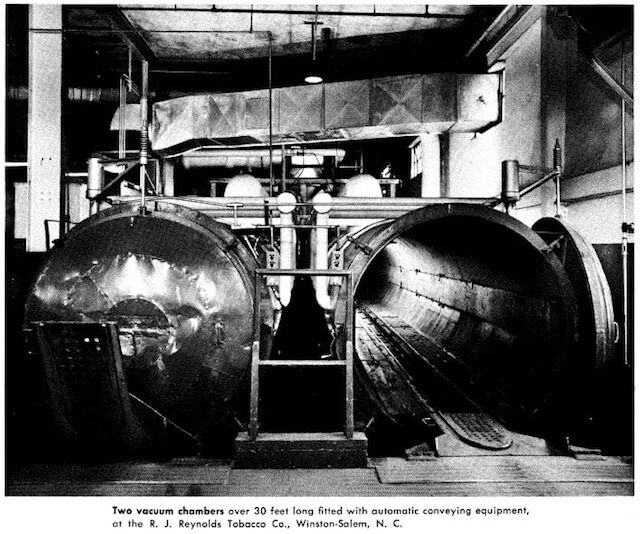

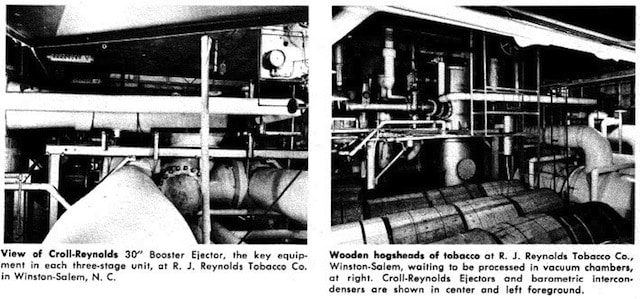

The Evactors are three-stage models. They pull vacuum from atmospheric pressure of 30″ mercury down to 0.2″, or better than 99 percent perfect, assuring maximum penetration of steam. From four to 30 hogsheads are placed in any of the four units using Croll Reynolds steam jets, and the vacuum chamber is sealed. The three booster jets operate sequentially, drawing off nearly all of the air in each of the hogsheads. When the desired vacuum is attained, low pressure saturated steam is admitted to the chamber. So effective is the vacuum that steam penetrates even the thick, woody stems of the tobacco leaf.

Evactors Draw Vacuum: After the initial steaming, the Croll Reynolds Evactors are again used to draw another vacuum. The process may be repeated as many as three times, depending on the original moisture content of the hogshead. It adds as much as 25 pounds of moisture to a single hogshead – four times as much as the sweat room method, and much faster. Each complete cycle, including loading and unloading, takes 20 to 30 minutes.

The steam jet installation has the combined advantage of operating without moving parts, and of being actuated by only 100 pounds pressure of dry steam. The system is completely automatic. The 1936, 1937 and 1938 installations are still in uninterrupted service with no maintenance necessary to the steam jets other than periodic cleaning of the nozzles. Through use of the system, the Reynolds Tobacco Company has been able substantially to improve speed and product quality, while lowering costs.

Steam Jet Vacuum System Installed: For example, in 1936, R. J. Reynolds Tobacco Company of Winston-Salem, N. C., installed a steam jet vacuum system designed to moisturize the tobacco by first removing most of the air in the hogshead and then introducing steam to fill the vacuum. The process evenly and completely moisturizes the tobacco, making it pliable and less subject to breaking into unusable fines.

Steam Provided By Vacuum Pumps: The vacuum required for full penetration of moisture from steam is provided by simple and economical steam jet vacuum pumps. On the original, and on other installations in 1937 and 1938, steam jet Evactors, manufactured by Croll Reynolds Co., Inc., were used.

The Evactors are three-stage models. They pull vacuum from atmospheric pressure of 30″ mercury down to 0.2″, or better than 99 percent perfect, assuring maximum penetration of steam. From four to 30 hogsheads are placed in any of the four units using Croll Reynolds steam jets, and the vacuum chamber is sealed. The three booster jets operate sequentially, drawing off nearly all of the air in each of the hogsheads. When the desired vacuum is attained, low pressure saturated steam is admitted to the chamber. So effective is the vacuum that steam penetrates even the thick, woody stems of the tobacco leaf.

Evactors Draw Vacuum: After the initial steaming, the Croll Reynolds Evactors are again used to draw another vacuum. The process may be repeated as many as three times, depending on the original moisture content of the hogshead. It adds as much as 25 pounds of moisture to a single hogshead – four times as much as the sweat room method, and much faster. Each complete cycle, including loading and unloading, takes 20 to 30 minutes.

The steam jet installation has the combined advantage of operating without moving parts, and of being actuated by only 100 pounds pressure of dry steam. The system is completely automatic. The 1936, 1937 and 1938 installations are still in uninterrupted service with no maintenance necessary to the steam jets other than periodic cleaning of the nozzles. Through use of the system, the Reynolds Tobacco Company has been able substantially to improve speed and product quality, while lowering costs.

Steam Jet Vacuum System Installed: For example, in 1936, R. J. Reynolds Tobacco Company of Winston-Salem, N. C., installed a steam jet vacuum system designed to moisturize the tobacco by first removing most of the air in the hogshead and then introducing steam to fill the vacuum. The process evenly and completely moisturizes the tobacco, making it pliable and less subject to breaking into unusable fines.

Steam Provided By Vacuum Pumps: The vacuum required for full penetration of moisture from steam is provided by simple and economical steam jet vacuum pumps. On the original, and on other installations in 1937 and 1938, steam jet Evactors, manufactured by Croll Reynolds Co., Inc., were used.

The Evactors are three-stage models. They pull vacuum from atmospheric pressure of 30″ mercury down to 0.2″, or better than 99 percent perfect, assuring maximum penetration of steam. From four to 30 hogsheads are placed in any of the four units using Croll Reynolds steam jets, and the vacuum chamber is sealed. The three booster jets operate sequentially, drawing off nearly all of the air in each of the hogsheads. When the desired vacuum is attained, low pressure saturated steam is admitted to the chamber. So effective is the vacuum that steam penetrates even the thick, woody stems of the tobacco leaf.

Evactors Draw Vacuum: After the initial steaming, the Croll Reynolds Evactors are again used to draw another vacuum. The process may be repeated as many as three times, depending on the original moisture content of the hogshead. It adds as much as 25 pounds of moisture to a single hogshead – four times as much as the sweat room method, and much faster. Each complete cycle, including loading and unloading, takes 20 to 30 minutes.

The steam jet installation has the combined advantage of operating without moving parts, and of being actuated by only 100 pounds pressure of dry steam. The system is completely automatic. The 1936, 1937 and 1938 installations are still in uninterrupted service with no maintenance necessary to the steam jets other than periodic cleaning of the nozzles. Through use of the system, the Reynolds Tobacco Company has been able substantially to improve speed and product quality, while lowering costs.

Steam Jet Vacuum System Installed: For example, in 1936, R. J. Reynolds Tobacco Company of Winston-Salem, N. C., installed a steam jet vacuum system designed to moisturize the tobacco by first removing most of the air in the hogshead and then introducing steam to fill the vacuum. The process evenly and completely moisturizes the tobacco, making it pliable and less subject to breaking into unusable fines.

Steam Provided By Vacuum Pumps: The vacuum required for full penetration of moisture from steam is provided by simple and economical steam jet vacuum pumps. On the original, and on other installations in 1937 and 1938, steam jet Evactors, manufactured by Croll Reynolds Co., Inc., were used.

The Evactors are three-stage models. They pull vacuum from atmospheric pressure of 30″ mercury down to 0.2″, or better than 99 percent perfect, assuring maximum penetration of steam. From four to 30 hogsheads are placed in any of the four units using Croll Reynolds steam jets, and the vacuum chamber is sealed. The three booster jets operate sequentially, drawing off nearly all of the air in each of the hogsheads. When the desired vacuum is attained, low pressure saturated steam is admitted to the chamber. So effective is the vacuum that steam penetrates even the thick, woody stems of the tobacco leaf.

Evactors Draw Vacuum: After the initial steaming, the Croll Reynolds Evactors are again used to draw another vacuum. The process may be repeated as many as three times, depending on the original moisture content of the hogshead. It adds as much as 25 pounds of moisture to a single hogshead – four times as much as the sweat room method, and much faster. Each complete cycle, including loading and unloading, takes 20 to 30 minutes.

The steam jet installation has the combined advantage of operating without moving parts, and of being actuated by only 100 pounds pressure of dry steam. The system is completely automatic. The 1936, 1937 and 1938 installations are still in uninterrupted service with no maintenance necessary to the steam jets other than periodic cleaning of the nozzles. Through use of the system, the Reynolds Tobacco Company has been able substantially to improve speed and product quality, while lowering costs.

Storage:

Vacuum Cooling Process Aids in Tobacco Storage Problem

The American Leaf Organization of the Imperial Tobacco Company of Great Britain and Ireland, purchases, processes and ships flue-cured tobacco to its parent company in Great Britain. The flue-cured marketing season runs from August through December during which time approximately one billion pounds of tobacco arc sold.

The tobacco marketing pattern in the United States creates a peak sales period lasting about six weeks during September and October, during which processors must purchase at a rate considerably in excess of their processing capacities in order to meet raw material requirements.

In recent years, increasing purchases, combined with a shorter selling season and a reduction in suitable redrying facilities brought about by the increased use of threshing, have intensified this problem.

Effects Of Storage: Tobacco as purchased can be stored for only a short period of time. The normal period between purchasing and processing is one to two weeks. Due to its high moisture content (18 to 20 percent) there is a constant danger of damage to the product in the form of fungal molds.

Finding a method of extending the period during which unredried tobacco could be safely stored appeared a more logical alternative to enlarging threshing and redrying facilities that would be needed for only a short time each season.

Experimental Method: Â On the assumption that reduced temperature storage would retard the growth-of-the-flora responsible for mold on tobacco. Imperial began experiments along this line in 1963. The container in which unredried leaf tobacco arrives at the processing plants is a hogshead containing approximately 800 pounds of tobacco.

If a hogshead was placed in a room refrigerated to the desired temperature (60° F in the initial work), heat transfer from the center of this mass to the air would take sufficiently long that damage might occur at the center before it had a chance to cool. For this reason, a method of quickly and uniformly cooling the entire contents of a hogshead was needed. Cooling by the rapid evaporation in a vacuum of some of the water on the tobacco appeared to be a practical approach.

Initial experiments involving cooling in a small existing vacuum chamber and storage in an insulated room were promising to the point that, for the 1964 season, a special vacuum chamber for cooling was constructed and 40 thousand square feet of the Wilson, North Carolina Imperial plant were temporarily fitted with air conditioning equipment sized to maintain the area at 60° F against ambient heat load.

Prior to the 1965 season, 90 thousand square feet of storage permanently equipped with air conditioning equipment capable of maintaining the temperature at 50° F were added to the plant. The target storage temperatures in both the initial work and the present installation were based on economic equipment and construction considerations. Storage temperatures below 50° would probably give a longer storage capability but would necessitate special building construction and provisions for air dehumidification.

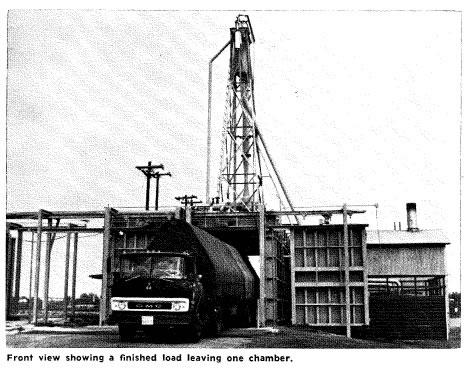

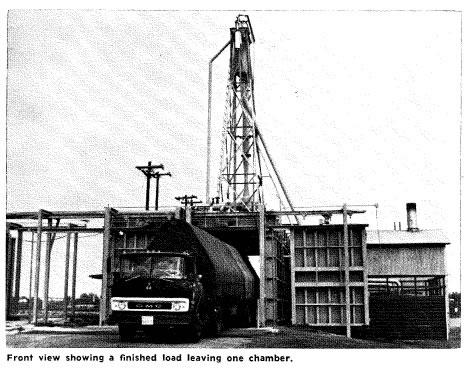

Equipment Utilized: The vacuum cooling units chosen for this initial installation consisted of two separate 6000-cubic-foot chambers and a two-part Croll Reynolds Chill-Vactor vacuum system utilizing steam jet ejectors. Each of the two chambers installed at Wilson is large enough to hold a tractor trailer unit loaded with thirty hogsheads of tobacco. The two part Croll Reynolds system, one for the removal of air from the chamber, and the other for evaporation of water, are alternated between the two chambers to give continuous cooling. This special arrangement results in a cooling production rate of approximately 24,000 pounds of tobacco per hour.

The Process: The hogsheads arrive at the Wilson plant on flat bed trailers. Loads designated for cooling rather than immediate processing are taken to the cooler where the trailer is unhooked and the load cooled.

When the process is completed the tractor is reconnected to the load and the tobacco is taken through the normal receiving process with the cool hogsheads placed in the air conditioned storage.

Effects Of Storage: Tobacco as purchased can be stored for only a short period of time. The normal period between purchasing and processing is one to two weeks. Due to its high moisture content (18 to 20 percent) there is a constant danger of damage to the product in the form of fungal molds.

Finding a method of extending the period during which unredried tobacco could be safely stored appeared a more logical alternative to enlarging threshing and redrying facilities that would be needed for only a short time each season.

Experimental Method: Â On the assumption that reduced temperature storage would retard the growth-of-the-flora responsible for mold on tobacco. Imperial began experiments along this line in 1963. The container in which unredried leaf tobacco arrives at the processing plants is a hogshead containing approximately 800 pounds of tobacco.

If a hogshead was placed in a room refrigerated to the desired temperature (60° F in the initial work), heat transfer from the center of this mass to the air would take sufficiently long that damage might occur at the center before it had a chance to cool. For this reason, a method of quickly and uniformly cooling the entire contents of a hogshead was needed. Cooling by the rapid evaporation in a vacuum of some of the water on the tobacco appeared to be a practical approach.

Initial experiments involving cooling in a small existing vacuum chamber and storage in an insulated room were promising to the point that, for the 1964 season, a special vacuum chamber for cooling was constructed and 40 thousand square feet of the Wilson, North Carolina Imperial plant were temporarily fitted with air conditioning equipment sized to maintain the area at 60° F against ambient heat load.

Prior to the 1965 season, 90 thousand square feet of storage permanently equipped with air conditioning equipment capable of maintaining the temperature at 50° F were added to the plant. The target storage temperatures in both the initial work and the present installation were based on economic equipment and construction considerations. Storage temperatures below 50° would probably give a longer storage capability but would necessitate special building construction and provisions for air dehumidification.

Equipment Utilized: The vacuum cooling units chosen for this initial installation consisted of two separate 6000-cubic-foot chambers and a two-part Croll Reynolds Chill-Vactor vacuum system utilizing steam jet ejectors. Each of the two chambers installed at Wilson is large enough to hold a tractor trailer unit loaded with thirty hogsheads of tobacco. The two part Croll Reynolds system, one for the removal of air from the chamber, and the other for evaporation of water, are alternated between the two chambers to give continuous cooling. This special arrangement results in a cooling production rate of approximately 24,000 pounds of tobacco per hour.

The Process: The hogsheads arrive at the Wilson plant on flat bed trailers. Loads designated for cooling rather than immediate processing are taken to the cooler where the trailer is unhooked and the load cooled.

When the process is completed the tractor is reconnected to the load and the tobacco is taken through the normal receiving process with the cool hogsheads placed in the air conditioned storage.

Use of the trailer-sized chambers is extremely convenient; but it necessitates more air removal than with a chamber designed for the hogsheads only. However, the elimination of the extra handling step more than pays for the increased size of the chamber.

Leaf tobacco at the normal temperature and moisture content from the market will cool to approximately 40°F upon exposure to a pressure of 0.1 to 0.2 inches of mercury absolute for one hour. Flue-cured tobacco has a heat capacity of approximately 0.5 BTU/ pound °F and is normally received at 75 to 80°F, necessitating the removal of approximately 1.5 percent moisture or approximately 400 pounds of water from a 30-hogshead load.

Use of the trailer-sized chambers is extremely convenient; but it necessitates more air removal than with a chamber designed for the hogsheads only. However, the elimination of the extra handling step more than pays for the increased size of the chamber.

Leaf tobacco at the normal temperature and moisture content from the market will cool to approximately 40°F upon exposure to a pressure of 0.1 to 0.2 inches of mercury absolute for one hour. Flue-cured tobacco has a heat capacity of approximately 0.5 BTU/ pound °F and is normally received at 75 to 80°F, necessitating the removal of approximately 1.5 percent moisture or approximately 400 pounds of water from a 30-hogshead load.

The three stage ejector system was designed to handle 450 pounds per hour of water vapor at 0.15 inches of mercury absolute.

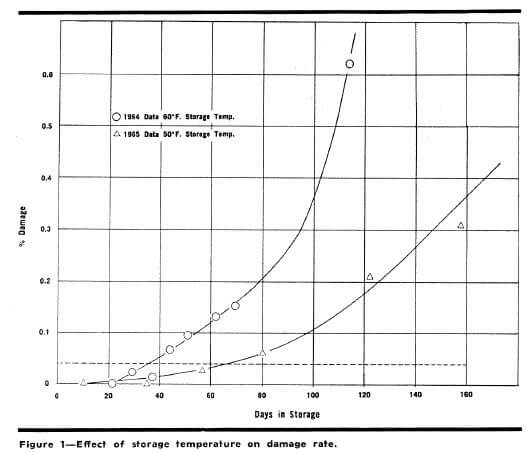

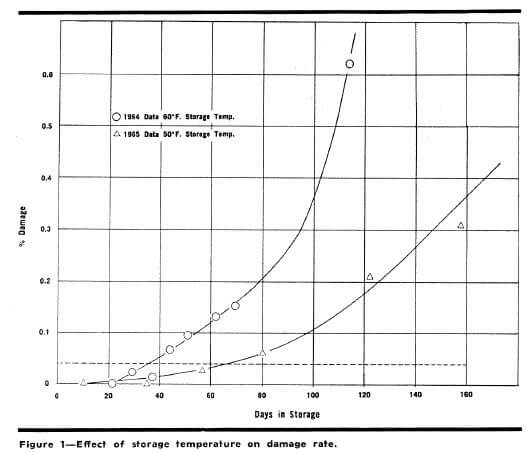

Tobacco Behavior: The rate of damage versus the length of time in storage at temperatures of 50°F and 60°F on the same grade of tobacco is illustrated in the plot in Figure 1. The horizontal dotted line indicates the normal damage level of uncooled tobacco in this grade at the time of processing.

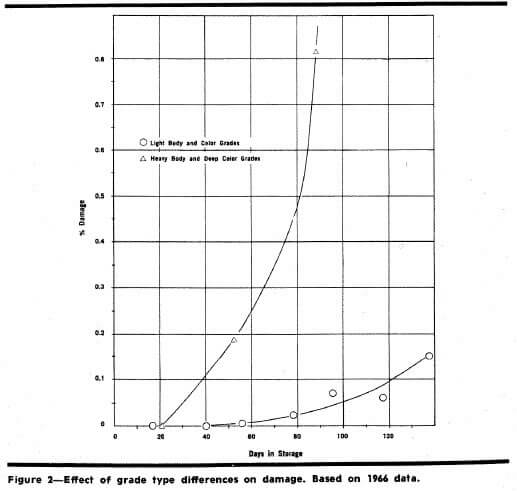

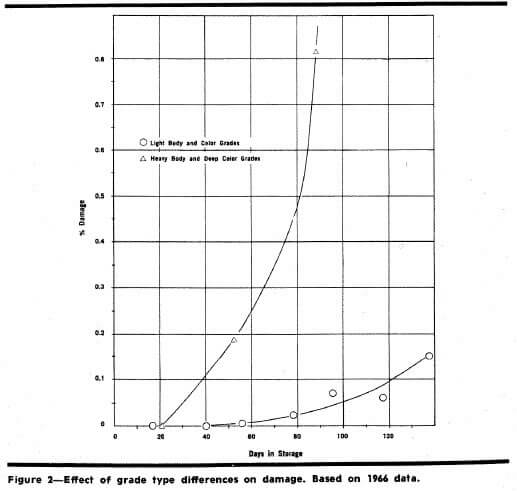

Different grades of tobacco behave quite differently when stored using the vacuum cooling and subsequent cold storage methods. The differences are not necessarily a function of differences in initial moisture contents. It has been the experience of the company that just as in the case of storing without cooling, the grades characterized by thin to medium body and light color keep much better than those characterized by heavy body and dark color. This is illustrated in a time plot of the damage rate in storage for these two grades (Figure 2) .

Since the initial installation in 1964, over 35 million pounds of tobacco have been vacuum cooled and stored by the company. The vacuum cooling method and subsequent storing at 50°F has allowed the company to extend the safekeeping period of flue-cured unredried light bodied tobacco from one or two weeks to twelve weeks and for the heavier grades to a safekeeping period of five weeks.

Under present circumstances, there is little doubt that the vacuum cooling process is a logical solution to Imperial’s Wilson, North Carolina, tobacco storage problem.

By: S.E. Stout – Research & Technical Department, The Imperial Tobacco Company (of Great Britain & Ireland), Limited Wilson, N.C.

The three stage ejector system was designed to handle 450 pounds per hour of water vapor at 0.15 inches of mercury absolute.

Tobacco Behavior: The rate of damage versus the length of time in storage at temperatures of 50°F and 60°F on the same grade of tobacco is illustrated in the plot in Figure 1. The horizontal dotted line indicates the normal damage level of uncooled tobacco in this grade at the time of processing.

Different grades of tobacco behave quite differently when stored using the vacuum cooling and subsequent cold storage methods. The differences are not necessarily a function of differences in initial moisture contents. It has been the experience of the company that just as in the case of storing without cooling, the grades characterized by thin to medium body and light color keep much better than those characterized by heavy body and dark color. This is illustrated in a time plot of the damage rate in storage for these two grades (Figure 2) .

Since the initial installation in 1964, over 35 million pounds of tobacco have been vacuum cooled and stored by the company. The vacuum cooling method and subsequent storing at 50°F has allowed the company to extend the safekeeping period of flue-cured unredried light bodied tobacco from one or two weeks to twelve weeks and for the heavier grades to a safekeeping period of five weeks.

Under present circumstances, there is little doubt that the vacuum cooling process is a logical solution to Imperial’s Wilson, North Carolina, tobacco storage problem.

By: S.E. Stout – Research & Technical Department, The Imperial Tobacco Company (of Great Britain & Ireland), Limited Wilson, N.C.

Effects Of Storage: Tobacco as purchased can be stored for only a short period of time. The normal period between purchasing and processing is one to two weeks. Due to its high moisture content (18 to 20 percent) there is a constant danger of damage to the product in the form of fungal molds.

Finding a method of extending the period during which unredried tobacco could be safely stored appeared a more logical alternative to enlarging threshing and redrying facilities that would be needed for only a short time each season.

Experimental Method: Â On the assumption that reduced temperature storage would retard the growth-of-the-flora responsible for mold on tobacco. Imperial began experiments along this line in 1963. The container in which unredried leaf tobacco arrives at the processing plants is a hogshead containing approximately 800 pounds of tobacco.

If a hogshead was placed in a room refrigerated to the desired temperature (60° F in the initial work), heat transfer from the center of this mass to the air would take sufficiently long that damage might occur at the center before it had a chance to cool. For this reason, a method of quickly and uniformly cooling the entire contents of a hogshead was needed. Cooling by the rapid evaporation in a vacuum of some of the water on the tobacco appeared to be a practical approach.

Initial experiments involving cooling in a small existing vacuum chamber and storage in an insulated room were promising to the point that, for the 1964 season, a special vacuum chamber for cooling was constructed and 40 thousand square feet of the Wilson, North Carolina Imperial plant were temporarily fitted with air conditioning equipment sized to maintain the area at 60° F against ambient heat load.

Prior to the 1965 season, 90 thousand square feet of storage permanently equipped with air conditioning equipment capable of maintaining the temperature at 50° F were added to the plant. The target storage temperatures in both the initial work and the present installation were based on economic equipment and construction considerations. Storage temperatures below 50° would probably give a longer storage capability but would necessitate special building construction and provisions for air dehumidification.

Equipment Utilized: The vacuum cooling units chosen for this initial installation consisted of two separate 6000-cubic-foot chambers and a two-part Croll Reynolds Chill-Vactor vacuum system utilizing steam jet ejectors. Each of the two chambers installed at Wilson is large enough to hold a tractor trailer unit loaded with thirty hogsheads of tobacco. The two part Croll Reynolds system, one for the removal of air from the chamber, and the other for evaporation of water, are alternated between the two chambers to give continuous cooling. This special arrangement results in a cooling production rate of approximately 24,000 pounds of tobacco per hour.

The Process: The hogsheads arrive at the Wilson plant on flat bed trailers. Loads designated for cooling rather than immediate processing are taken to the cooler where the trailer is unhooked and the load cooled.

When the process is completed the tractor is reconnected to the load and the tobacco is taken through the normal receiving process with the cool hogsheads placed in the air conditioned storage.

Effects Of Storage: Tobacco as purchased can be stored for only a short period of time. The normal period between purchasing and processing is one to two weeks. Due to its high moisture content (18 to 20 percent) there is a constant danger of damage to the product in the form of fungal molds.

Finding a method of extending the period during which unredried tobacco could be safely stored appeared a more logical alternative to enlarging threshing and redrying facilities that would be needed for only a short time each season.

Experimental Method: Â On the assumption that reduced temperature storage would retard the growth-of-the-flora responsible for mold on tobacco. Imperial began experiments along this line in 1963. The container in which unredried leaf tobacco arrives at the processing plants is a hogshead containing approximately 800 pounds of tobacco.

If a hogshead was placed in a room refrigerated to the desired temperature (60° F in the initial work), heat transfer from the center of this mass to the air would take sufficiently long that damage might occur at the center before it had a chance to cool. For this reason, a method of quickly and uniformly cooling the entire contents of a hogshead was needed. Cooling by the rapid evaporation in a vacuum of some of the water on the tobacco appeared to be a practical approach.

Initial experiments involving cooling in a small existing vacuum chamber and storage in an insulated room were promising to the point that, for the 1964 season, a special vacuum chamber for cooling was constructed and 40 thousand square feet of the Wilson, North Carolina Imperial plant were temporarily fitted with air conditioning equipment sized to maintain the area at 60° F against ambient heat load.

Prior to the 1965 season, 90 thousand square feet of storage permanently equipped with air conditioning equipment capable of maintaining the temperature at 50° F were added to the plant. The target storage temperatures in both the initial work and the present installation were based on economic equipment and construction considerations. Storage temperatures below 50° would probably give a longer storage capability but would necessitate special building construction and provisions for air dehumidification.

Equipment Utilized: The vacuum cooling units chosen for this initial installation consisted of two separate 6000-cubic-foot chambers and a two-part Croll Reynolds Chill-Vactor vacuum system utilizing steam jet ejectors. Each of the two chambers installed at Wilson is large enough to hold a tractor trailer unit loaded with thirty hogsheads of tobacco. The two part Croll Reynolds system, one for the removal of air from the chamber, and the other for evaporation of water, are alternated between the two chambers to give continuous cooling. This special arrangement results in a cooling production rate of approximately 24,000 pounds of tobacco per hour.

The Process: The hogsheads arrive at the Wilson plant on flat bed trailers. Loads designated for cooling rather than immediate processing are taken to the cooler where the trailer is unhooked and the load cooled.

When the process is completed the tractor is reconnected to the load and the tobacco is taken through the normal receiving process with the cool hogsheads placed in the air conditioned storage.

Use of the trailer-sized chambers is extremely convenient; but it necessitates more air removal than with a chamber designed for the hogsheads only. However, the elimination of the extra handling step more than pays for the increased size of the chamber.

Leaf tobacco at the normal temperature and moisture content from the market will cool to approximately 40°F upon exposure to a pressure of 0.1 to 0.2 inches of mercury absolute for one hour. Flue-cured tobacco has a heat capacity of approximately 0.5 BTU/ pound °F and is normally received at 75 to 80°F, necessitating the removal of approximately 1.5 percent moisture or approximately 400 pounds of water from a 30-hogshead load.

Use of the trailer-sized chambers is extremely convenient; but it necessitates more air removal than with a chamber designed for the hogsheads only. However, the elimination of the extra handling step more than pays for the increased size of the chamber.

Leaf tobacco at the normal temperature and moisture content from the market will cool to approximately 40°F upon exposure to a pressure of 0.1 to 0.2 inches of mercury absolute for one hour. Flue-cured tobacco has a heat capacity of approximately 0.5 BTU/ pound °F and is normally received at 75 to 80°F, necessitating the removal of approximately 1.5 percent moisture or approximately 400 pounds of water from a 30-hogshead load.

The three stage ejector system was designed to handle 450 pounds per hour of water vapor at 0.15 inches of mercury absolute.

Tobacco Behavior: The rate of damage versus the length of time in storage at temperatures of 50°F and 60°F on the same grade of tobacco is illustrated in the plot in Figure 1. The horizontal dotted line indicates the normal damage level of uncooled tobacco in this grade at the time of processing.

Different grades of tobacco behave quite differently when stored using the vacuum cooling and subsequent cold storage methods. The differences are not necessarily a function of differences in initial moisture contents. It has been the experience of the company that just as in the case of storing without cooling, the grades characterized by thin to medium body and light color keep much better than those characterized by heavy body and dark color. This is illustrated in a time plot of the damage rate in storage for these two grades (Figure 2) .

Since the initial installation in 1964, over 35 million pounds of tobacco have been vacuum cooled and stored by the company. The vacuum cooling method and subsequent storing at 50°F has allowed the company to extend the safekeeping period of flue-cured unredried light bodied tobacco from one or two weeks to twelve weeks and for the heavier grades to a safekeeping period of five weeks.

Under present circumstances, there is little doubt that the vacuum cooling process is a logical solution to Imperial’s Wilson, North Carolina, tobacco storage problem.

By: S.E. Stout – Research & Technical Department, The Imperial Tobacco Company (of Great Britain & Ireland), Limited Wilson, N.C.

The three stage ejector system was designed to handle 450 pounds per hour of water vapor at 0.15 inches of mercury absolute.

Tobacco Behavior: The rate of damage versus the length of time in storage at temperatures of 50°F and 60°F on the same grade of tobacco is illustrated in the plot in Figure 1. The horizontal dotted line indicates the normal damage level of uncooled tobacco in this grade at the time of processing.

Different grades of tobacco behave quite differently when stored using the vacuum cooling and subsequent cold storage methods. The differences are not necessarily a function of differences in initial moisture contents. It has been the experience of the company that just as in the case of storing without cooling, the grades characterized by thin to medium body and light color keep much better than those characterized by heavy body and dark color. This is illustrated in a time plot of the damage rate in storage for these two grades (Figure 2) .

Since the initial installation in 1964, over 35 million pounds of tobacco have been vacuum cooled and stored by the company. The vacuum cooling method and subsequent storing at 50°F has allowed the company to extend the safekeeping period of flue-cured unredried light bodied tobacco from one or two weeks to twelve weeks and for the heavier grades to a safekeeping period of five weeks.

Under present circumstances, there is little doubt that the vacuum cooling process is a logical solution to Imperial’s Wilson, North Carolina, tobacco storage problem.

By: S.E. Stout – Research & Technical Department, The Imperial Tobacco Company (of Great Britain & Ireland), Limited Wilson, N.C. For your vacuum system requirements, contact our US headquarters in Parsippany or our representative offices in your area.