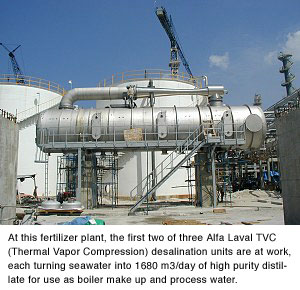

At a fertilizer plant in coastal Indonesia, the first two of three Alfa Laval Type TVC (Thermal Vapor Compression) desalination units are at work, each turning seawater into 1680 m3/day of high-purity distillate for use as boiler makeup and process water. The two units were commissioned in December 2001 and have been running without problems ever since; a third plant, also rated at 1680 m3/day, is still in the installation stage.

The desalination units combine a number of features promising most output for least input, with low maintenance an important ancillary benefit.

TVC (evaporative) desalination process is accomplished by Alfa Laval’s high-efficiency plate-type heat exchanger technology, which the company describes as pressed plate using a falling film (PPFF). Steam for the evaporative process is provided by the fertilizer plant boilers, with energy saved by operating in a vacuum (150 mbar abs) environment provided by ejector systems from Croll Reynolds Co., Inc., NJ. Efficiency is increased by the multi-effect evaporator. Energy balance for the process is further improved by the use of Croll Reynolds thermocompressors, which take spent steam from the last (cold) effect and recombine it with higher pressure steam from an external source for reuse at the first (hot) effect.

Plate Heat Exchange Boosts Efficiency: Alfa Laval’s concept of plate falling-film desalination has a thirty-year background in marine evaporators producing distilled water onboard cargo ships and cruise liners. Ten years ago the company translated the marine experience into land-based desalination for industrial applications.

In the PPFF process, seawater falls down one side of each titanium plate as a thin film, and evaporates because of the heat being transferred from condensing water vapor on the other side of the plate. The vapor is collected, condensed and extracted as pure distilled water, while the brine is returned to the sea.

Compared with conventional tube-and-shell desalination systems, the PPFF configuration achieves greater thermal efficiency. That means installations can be smaller with lower site requirements and a lower capital cost.

Process Under Vacuum: Placing the evaporative process under vacuum allows the condensing water to boil at a much lower temperature, resulting in considerable energy savings. The Croll Reynolds ejector vacuum system for each desalination unit consists of two ejector stages, each 100x100mm, and a vertical vapor-in-shell aftercondenser. The ejectors and condenser shell are stainless steel, and the condenser tubes are titanium with titanium-clad tubesheet.

Thermocompression Improves Plant Balance: In each desalination unit, a thermocompressor recompresses spent steam from the multi-effect evaporator, decreasing steam consumption and raising the efficiency of the system. Since the Indonesian plant employs primary energy — boiler bleed steam — the importance of efficient energy use is increased.

The thermocompressor uses high-pressure steam as a motive fluid to entrain the low-pressure spent steam from the process. The two fluids are combined in the mixing chamber and recompressed to an intermediate pressure through the diffuser, which reconverts velocity energy to pressure energy. For the Indonesian installation, each 900×900 mm thermocompressor has seven nozzles and a spray ring at discharge for desuperheating.

Lower Maintenance A Benefit: The plate-based desalination system is constructed from titanium and could be easily dismantled for manual cleaning should hard scaling takes place.

The ejectors and thermocompressor have no moving parts and are practically maintenance free. Lifespan of the reliable equipment often tops twenty-five years. The only recommended spare parts are nozzles — one for each ejector stage and seven for each thermocompressor — with gaskets.

By: Jens Bekker Nielsen, Project Manager – Alfa Laval Water Technology, Soborg, Denmark