Ejector technology maintains its essential place in the process of steel mill vacuum, degassing. At this steel producer, an upgrade of the vacuum-producing ejector systems exceeded the original equipment for performance and steam economy.

National Forge Company, Irivne, PA, is a totally integrated manufacturing facility. The mill’s capabilities extend from raw materials to finished product, including melting, forging, heat treating, machining, and extensive quality assurance. The company supplies a worldwide market with engine and compressor crankshafts, generator shafts, turbine rotors, pipe molds for centrifugal casting, and other precision components.

A single 45-ton basic electric-arc furnace produces all the steel the company uses, including carbon, alloy, and stainless steels, selected tool steels, and special proprietary steel alloys. All steel is vacuum processed to enhance its quality.

Vacuum Degassing: Vacuum degassing is an essential step in the production of modern quality steels. By removing dissolved hydrogen, oxygen, and some nitrogen, degassing produces cleaner, tougher and more ductile steel. In particular, degassing avoids the flaking and cracking caused by dissolved hydrogen in the steel.

In 1960, the process of vacuum degassing was very new. That year, National Forge installed a Dortmund-Hoerder vacuum lift process system, which is still the degassing method of choice at the company.

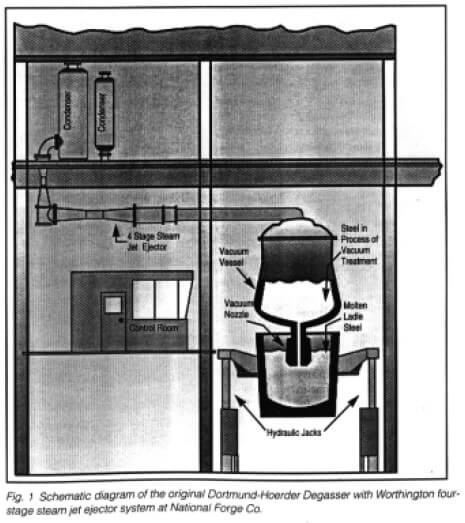

Process Details: In the Dortmund-Hoerder process, a ladle of molten steel is positioned under the vacuum vessel, and raised by hydraulic jacks until the vessel’s nozzle is immersed (Fig. 1). Under full vacuum, a 58-inch high column of steel is generated. The nozzle remains immersed in the molten steel, and the ladle is cycled up and down until the entire volume of the ladle has been exposed to vacuum.

The function of the ejectors in the degassing system is to pump hot, dirty gases out of the molten steel and evacuate them through the ejector stages and intercondensers. Steel in the ladle is at a temperature of approximately 3000 degrees F. Although off-gases are passed through a cooler before entering the ejector, they remain extremely hot.

In thirty minutes or less from final furnace tap to start of teem (pouring), the system effectively degasses a forty-ton load of molten metal. To achieve the equivalent removal of hydrogen by heat treating methods requires hundreds of hours.

The hydrogen content of the tapped metal (liquid steel just removed from the furnace) is generally on the order of four to five parts per million (ppm). To meet company quality standards removal of 50% or better is desired, with a finished hydrogen content between one and two ppm.

Considering The Ejector System Upgrade: When the vacuum lift system was originally installed, it was equipped with a Worthington four-stage steam jet ejector system, which included two intercondensers, to provide the necessary vacuum (see Fig. 1). Over the years, National Forge personnel maintained and repaired the ejector system as necessary.

After thirty-six years of successful operation, a drop in vacuum pressure alerted plant personnel that the ejectors were no longer capable of providing the 1000 micron vacuum as required by most steel specifications. Company engineers determined that in order to maintain a successful low-pressure environment and minimize the duration of the degassing process (to avoid excessive heat loss), it would be necessary to replace some of the vacuum equipment.

Since the fourth, or final stage ejector was relatively new and still in excellent shape, plant engineering personnel decided to replace only the first three stages of the ejector system.

Considering several suppliers, the forging company consulted Croll Reynolds Co., NJ. Jitu Patel, Croll Reynolds’ chief vacuum systems engineer, examined the existing system and determined that equipment could be supplied which would more than restore original performance.

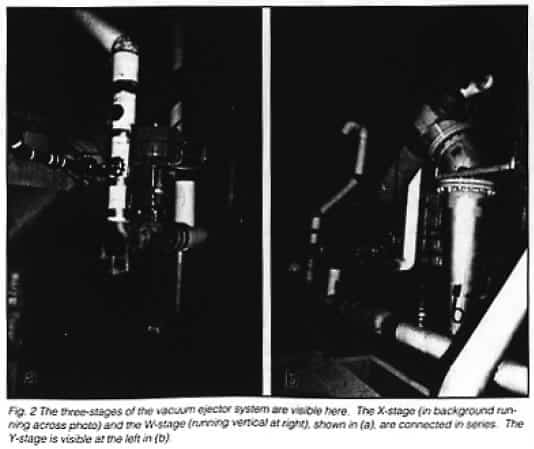

Three ejector stages, constructed from 303 stainless steel, were designed to work compatibly with existing system equipment. The W-stage ejector measures 16 x 16 in; the X-stage ejector is 16 x 14 in.; and the Y-stage ejector is 10 x 8 in. The W-X stages, which were assembled in series(Fig. 2), handle 60 lb/hr of 70 degrees F dry air equivalent at 0.024″ Hg absolute, discharging to 2 in. Hg abs. into the existing first intercondenser. The Y-stage ejector takes suction from the first intercondenser at 2 in. Hg abs and discharges to the existing second intercondenser at 7 in. Hg abs.

Installation and Performance Testing:Â The new ejector stages were installed in July 1997. Installation was managed by ADM Contractors, Warren, PA, working with National Forge pipefitters. The degassing system was operational in less than two weeks.

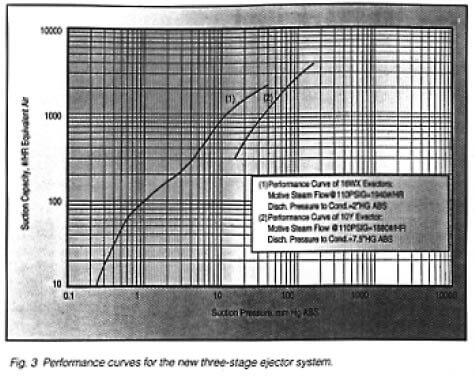

Croll Reynolds also performs bench pretesting of its new ejectors. When the new components were installed and tested, test data showed that the upgraded ejector system was achieving better than the original performance of the system it replaced (see Fig. 3).

National Forge operators can cross check the test curves of ejector energy efficiency by inspecting the boiler records. The original ejector system required about 10,000 lb/hr of 110 pig D & S motive steam; in its upgraded condition, the system’s steam usage is reduced to 8,000 to 9,000 lb/hr.

Maintenance Of The Ejectors: Because hot, dirty gases are continually being handled, the ejector system is frequently inspected for cleanliness. Before its replacement, the old system required cleaning every two weeks.

Thus far, the upgraded system has required no cleaning. Part of the improvement is attributable to the smooth surfaces of the new stainless steel elements. However, operators believe that the “clean” condition is more attributable to the seven-nozzle design of the X- and Y-stages. They believe that the multi-nozzle design provides better turbulence and scrubbing action through the diffuser.

Summary: National Forge finds its upgraded system of continuing benefit to its operation. Restoration or improvement of originally specified vacuum capability improves the performance of the vacuum degassed. It also speeds the degasser cycle, which reduces heat loss from the molten steel being treated. In addition, the higher efficiency has improved plant energy balance and provides a worthwhile cost savings for the company.

By: Robert D. Winter, P.E., Facilities Engineer and James E. Caldwell, Senior Staff Metallurgist, National Forge Company, Irivne, PA.